A laser module incorporates a laser diode, one or more lenses, drive electronics, and module housing. ProPhotonix designs and manufactures all our laser modules in-house giving you total control over the functionality and offers a wide range of customizations. This allows for designing a truly optimized high-performance laser for your application.

Filter |

|---|

Laser FAQs

What is a laser module?

What wavelengths are available in laser modules?

ProPhotonix offers a wide variety of wavelengths from 405nm to 1500nm with a maximum output power up to 2W.

What beam shapes are available in laser modules?

There are various beam shapes available including circular and elliptical spot, Gaussian and uniform lines, as well as optical patterns. This allows for a truly customized laser solution for your business.

Why use a digital interface?

Our digital laser modules offer more control over operational commands if your application requires it e.g output power and pulse conditions. Our digital interface is a simple and user-friendly way of controlling and monitoring the performance of your laser module.

How do you ensure maximum lifetime from a laser module?

Laser diodes generate heat in the process of emitting light. Typically, 10-30% of the power used to generate heat is converted to light, the rest is wasted as heat. This heat ends up warming the laser diode, the module, the optics and surrounding housing. We can manage the heat through a thermal pathway which allows the heat to flow away from the laser diode. Read more about how we ensure efficient thermal management in our laser modules here.

How does ProPhotonix develop custom laser modules?

The process starts with your requirements. Our engineers will collaborate with your engineering team to decide on the exact specifications required. Next, we develop a prototype with our in-house specialists and leverage their optics, electronics, thermal, software and mechanical expertise. We work through feedback you may have on the prototype and move onto the production stage. The process is highly collaborative from end to end. We like to think of it as an integrated partnership that is ongoing, and doesn’t come to an end once the product is delivered. We will work with you to ensure optimal performance throughout the life of the product.

Can the laser be pulsed?

Yes, but the maximum CW power should be observed

LED FAQs

Does ProPhotonix make LEDs?

ProPhotonix sources LEDs, mostly unpackaged LED chips, from reputable, established companies that make the LED wafers themselves. Sourcing the LEDs is a core competency developed from more than a decade of experience. The LEDs are selected based on wavelength, power, and price according to the specification of the product or goals and constraints of the custom design. We place these LEDs on a thermally efficient PCB substrate of our design, wire bond to complete the circuit, and assemble this “Light Engine” into a higher level assembly that can include optics, mechanics, thermal management features, as well as control electronics. By starting with the smallest, most basic building block, the LED chip itself, we have the most control possible for every aspect of the design and performance.

What is Chip-on-Board LED packaging?

Chip-on-Board (COB) LED packaging refers to placing the LED die directly on a PCB substrate where it is fixed by silvered epoxy or solder. The intended circuit is then completed with wire bonds between the LED chips and the PCB. Generally, an encapsulation, hard of soft, is used to protect the wire bonds and LEDs. As the LED chip is the smallest light building block available, the light engine itself can be a highly customized, application specific device with many LEDs with almost any spacing or array dimension. Multiple colors and driving circuits can be designed. Optics can be mounted directly to the PCB. The electronics if desired can be on or off the PCB (or light). The LED chips ranging in size generally from ~300 microns to 1-mm per side can be considered Lambertian emitters and have no integrated optics like common through-hole or surface mount devices. This allows the optical performance to be customized for the application starting with the most basic element. The chips are directly mounted to PCB substrate so the heat is removed from the LED more efficiently than through several intermediate junctions in a surface mount LED or through the leads in a through-hole LED package. In short Chip-on-Board is ideal for the highest performance or highly constrained applications.

Can you modify your standard product or create a new design for my needs?

Yes. Please tell us about your project and if it is something physically possible with LEDs and commercially viable, we can do it.

What colors or wavelengths are available?

LEDs are available in many wavelengths from 250 nm in the UV to several microns in the IR. In some parts of the visible spectrum an LED with a peak wavelength may be available every 5-10nm. However in some parts of the spectrum there are no LEDs available due to technology limitations.

Can you put multiple wavelengths in a single light?

Yes. We do so commonly for custom OEM projects. Please contact us for more information.

Can I replicate the spectrum of a fluorescent, halogen or other black body legacy lighting technologies?

Not exactly but It might be possible to provide enough optical power for your application at specific wavelength ranges. White LEDs do not replicate the spectrum of legacy lighting technologies but can appear very similar to the human eye.

What color temperature are your white LEDs and are other color temperatures available?

It varies from product to product but generally in the cool white range between 5000-7000 deg Kelvin. We will consider requests for other color temperatures.

Can an LED light be supplied with peak wavelength specified at a specific, single nanometer?

Unfortunately we cannot. LEDs can only be ordered from our suppliers in bins of peak wavelength and optical power. The peak wavelength range of these bins are generally +/-5 or +/-10 nm wide. To get narrower bins is sometimes possible. However, to get a narrower peak wavelength range requires further sorting from larger lot of LEDs purchased. Ultimately, it would be very difficult to control the wavelength to within a single nanometer due to fluctuations with current and temperature. If those are tightly controlled it may be possible.

Does the wavelength change over time?

For red or infrared LEDs the wavelength generally increases. For green LEDs, the wavelength generally increases at lower currents. Blue LEDs are relatively stable and change very little. Thermal management is key. Once the system reaches steady state temperature its wavelength will remain stable unless the current is changed.

What is the lifetime of your LED products?

MTBF is not generally used in the LED industry because LEDs when used properly, that is with good heat sinking and without excessive current, don’t generally catastrophically fail. Their light output will gradually decrease from the initial maximum. LED lifetime is generally defined by the time it takes for the maximum optical power to decrease to 70% of its original. This is termed “L70” by the larger LED industry.

We rely on the specification of the LEDs run at rated current by our vendors to estimate lifetime. The lifetime will be at least 50,000 hours and could be 100,000. Our lights feature better thermal management than is typically assumed so even when run continuously at higher currents we expect to achieve 50,000 hours at minimum. Strobing or intermittent operation generally increases the effective lifetime because heat is not built up and the light is off more often than on. MTBFs will be 100,000 hours or more.

Can your LED products be strobed?

Yes.

Strobing is generally done to stop motion in a machine vision application or produce a very brief pulse of light much brighter than at the rated current. Remember an overdriven pulse that might be 10 times brighter will put out the same amount of light as the light would if left on at the original current for 10 times longer. Intensity in a camera exposure or process is directly proportional to the length of the time the light is on and the amount of light emitted per unit time. The main function of strobing is to stop motion with fast well timed pulses. Overdriving allows for either adequate exposure levels or shorter pulses and therefore faster processes. Strobing or simple on/off control also reduces the affects of heat on the lights.

Strobing or frequent on/off operation does not damage LED lights so long as it is done properly. However, it is very easy to damage LED lights by strobing them if it is done improperly. All strobing is done at your risk.

The LEDs themselves have response times of the order of nanoseconds and track the power supplied to them extremely closely. However, the relation between light output and current is not linear at high currents. The efficiency of the LED decreases and effectually rolls over. If you are pulsing in this regime you have a high risk of damaging the light. For support in determining the maximum safe strobe current for your application contact us.

We offer strobe controllers that can strobe as fast as a microsecond and offer programmable deterministic currents, pulse widths, delay, and duty cycle limits. With these or your own current controller it is often possible to overdrive our lights by as much as 10-15 times safely. Note that high pulse currents are only safe for short pulse widths, generally a millisecond or less, and low duty cycles, generally 10% or less.

The COBRA Slim linescan light features optional strobing functionality.

The SpecBright product family, when configured for current control, can be safely overdriven many times. The exactly amount depends on the wavelength, thermal management, pulse width, and duty cycle. SpecBright 24VDC configured lights should not be overdriven though they can be strobed for very short pulses without risk.

Unfortunately we cannot guarantee pulsed output intensities and overdriven pulsing is done at the users risk.

How bright are your LED products in Watts like my fluorescent or halogen lights are rated?

While many high brightness LEDs available from major manufacturers are described as products as 1W, 3W, or 5W devices this is not a good description of how an LED light will perform, just as it is not a good description of how a fluorescent or halogen light will perform. This is a description of the electrical power draw, only a fraction of which is converted to optical power and a fraction of that reaches where it is needed.

We specify our products or try to define specifications for custom designs in Watts per square meter (W/m2) as projected over a given area at specific distance from the source. That being said our lights or designs produce under a Watt of optical power to several 100 Watts of optical power. Direct comparison with legacy lighting technologies is difficult and requires very controlled testing. However, our customers have confirmed we make lights that can be brighter than halogen and other lighting technologies.

Can I power your lights from 24VDC?

Yes, almost all of our standard products can be configured to be powered from 24VDC. The only exception is the SpecBright Spot light product which requires a constant current controller such as our CMP-M-400. That controller takes 24VDC input.

Do you offer lights configured for constant current control?

Yes, all of our lights can be configured for constant current control. The COBRA product family features an integrated light specific current controller. The SpecBright products can all be configured as constant current controlled lights for no extra cost as standard. While this requires an extra part in addition to the power supply–a current controller such as our CMP-M-400 controller, a CMS strobe controller, or your own controller—the benefits are potentially higher brightness, more linear intensity control, overdriving potential, less heat generated, and better stability.

The light is hot to the touch. Is this bad?

The body of the light needs to be kept below 45 degrees Celsius. If the body of the light is too hot to hold onto the light needs better heat sinking or other thermal management. Lower the current, add a fan, and/or add a heat sink. We offer optional modular heat sink accessories for the SpecBright range. Your fixturing if it is a metal such as aluminum with sufficient surface area can also function as the heat sink. We offer modular heat sinks because smaller lights are easier to integrate and in some application either the fixturing is an adequate heat sink or the light is run a low enough power or duty cycle (strobed) that heat sinking is not a concern.

Do I need to order the optional heat sink for accessory with a SpecBright?

If you are running the light at or near full power for a few minutes or longer you need heat sinking. The body of the light must be kept below 45 degrees Celsius. If you attach our heat sink accessory you can be assured that for normal factory environments the light will be within safe operating limits. Your own fixturing may also be just as good. We made the heat sinks modular to allow you the flexibility when integrating our lights into your system.

Your light has a big heat sink on it. Does that mean it is poorly designed and likely to fail prematurely?

The opposite is true. The fact that our lights get hot is a sign that the thermal design is very good. It means that the heat is getting away from the LEDs themselves which is what leads to premature failure, shorter lifetime, and short term optical instability (optical power and wavelength). For situation where the LEDs are being run high currents continuously such as in our COBRA line scan light product range a substantial heat sink, possibly with fans, is required to dissipate the heat. Similarly, if the SpecBrights are being run at or near full power for more than a few minutes they should be attached to a heat sink such as our modular heat sink accessories. If the case temperature is 45 degrees Celsius or higher, too hot to hold on to, the lights need an adequate heat sink.

UVC LED FAQ's

What systems do you have ready to use?

Visit our UVC LED Curing Systems Page for information on our range of UVC Solutions. We have the COBRA Clean FX1 available in 265nm for test. We will have other wavelengths and form factors available very soon. Please contact us directly to find out about our roadmap.

Can your systems sterilize?

Our systems can be utilized for sterilization but the lamps effectiveness is largely dependent on the environmental conditions in which they are operating and how it is designed. ProPhotonix has more than 25 years of experience partnering with OEMs to develop innovative, reliable LED systems tailored to their specific application needs. We work closely with our partners to understand their application requirements and our multidisciplinary team of LED experts designs and manufactures high-performance LED solutions optimized for their application. Our aim is to deliver a competitive advantage for our customers.

What research have you done on the effectiveness of UV LED on viruses and bacteria?

ProPhotonix is a partner in a consortium that was awarded an EU Horizon 2020 grant to develop innovative reactor solutions for disinfection of water utilizing UVA and UVC based LED technologies. The consortium comprises three universities; University of Cambridge (UK), Rey Juan Carlos University (Spain) and Ulster University (UK) as well as two other partner companies; Delft IMP (Netherlands) a designer and manufacturer of nanostructured catalysis materials and FCC Aqualia (Spain), a global water management company. ProPhotonix’s role in the project is to deliver a number of UV LED based systems for these applications. More details can be found at https://www.prophotonix.com/wp-content/uploads/2020/03/ProPhotonix-UV-LED-Water-Disinfection.pdf

Can I treat a room with your systems?

Yes. UVC LED systems can be designed to treat a room. ProPhotonix has more than 25 years of experience partnering with OEMs to develop innovative, reliable LED systems tailored to their specific application needs. We work closely with our partners to understand their application requirements and our multidisciplinary team of LED experts designs and manufactures high-performance LED solutions optimized for their application. Our aim is to deliver a competitive advantage for our customers.

Ref. https://www.lightbulbs.com/blog/how-led-lights-are-making-hotels-cleaner

Is UV LED disinfection effective against COVID 19?

Preliminary research utilizing UV-C LEDs to combat SARS-COV is encouraging. UV LED manufacturer Seoul Viosys and SETi’s Violeds Technology proves 99.9% sterilization of Coronavirus (COVID-19) in 30 Seconds. Meanwhile, PuroLighting working with Dr. David Brenner from Columbia University confirmed that UVC light can be effective for combating SARS-COV. Additional studies are now needed to determine and confirm the specific dose response required to inactivate COVID-19 on different surfaces and materials.

Ref.

What are the key issues in using UV LED for these applications?

Ref. Lawal, O., Pagan, J. Hansen, M. 2017. When Will UV-C LEDs be Suit-able for Municipal Treatment? Conference Presentation. IUVA World Congress. 18 September 2017.

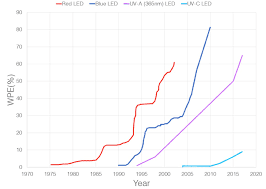

UV-C LEDs are a relatively new technology. As can be seen from the chart above, UVC LED efficiency low, below 10%. However, UVC LED development is following a similar rapid improvement profile that has occurred for other LED technologies such as red, blue and UV-A wavelengths.

Low efficiency also means that the lifetime of these LEDs is less than more mature LED technology. However, for some wavelengths, 10,000 hrs have been reported.

As applications are still being developed and LED manufacturers improve their processes, LED unit costs continue to reduce. However, the pricing is still not at the level of more mature LED wavelengths and commercially viable applications are limited for the next 3-5 years. As a result of the COVID-19 pandemic, there has been increased interest in UV-C LEDs which may increase this timeline.

What other factors impact the effectiveness of the system? e.g. time, shadowing

The presence of particles can protect microorganisms from UV, for example, UV is not effective in highly turbid water due to low transmissivity.

UV products cannot penetrate particles like dust or oils, so dirty surfaces will cause effectiveness to drop.

Some microorganisms have built up some immunity to UV. Therefore, a higher dose of UV must be deployed to kill these microorganisms. Indeed, the type of microorganism targeted can impact results. For example, 265nm is considered the optimum wavelength to use for disinfection but 275nm has been shown to disinfect E. Coli.

Microorganisms cannot be affected if they are not exposed to the light. Any area where a shadow occurs from an obstacle not allowing the UV light to shine will have no effect on the organism.

Ref. Li X, Cai M, Wang L, Niu F, Yang D, Zhang G. Evaluation survey of microbial disinfection methods in UV-LED water treatment systems. Sci Total Environ. 2019;659:1415-1427. doi:10.1016/j.scitotenv.2018.12.344

What characteristics of the light are important?

Wavelength, Irradiance and time are the most important factors.

Wavelength: UVC wavelength range is between 100nm to 300nm. Generally, UV-C germicidal wavelength at 265nm is the most effective to kill harmful microorganisms via molecular lesions of DNA and RNA in the air, water and on surfaces as this is the absorption peak of DNA and RNA. Disinfection can occur more efficiently at different wavelengths via different disinfection mechanisms such as cell wall degradation which will cause death. Sometimes the optimum peak wavelength may not be the best choice of wavelength. If an alternative LED wavelength delivers higher intensity and dose at a more efficient cost, it may be a better choice that the “optimum wavelength”.

Irradiance is a measure of how much UV energy falls on a particular surface point. Importantly, it is not the same as how strong a particular UV lamp is. A 10W lamp that emits UV in all directions, for example, may provide lower UV irradiance at a particular spot than a 5W lamp that focuses its UV output in a narrow beam.

Time: The effective UV energy density, or dose, is the amount of UV energy that falls on a surface for a particular time. It refers to the necessary UV energy required for micro-organisms (bacteria, viruses, algae in suspension…) to absorb to the point of being neutered or killed.

UV mercury lamps have been considered the best choice for disinfection and sterilization. Why is that?

Historically, mercury lamps have been the only option for UV disinfection and sterilization. With advancements in UV LED technology, there are new options that are smaller, more robust, toxin-free, long lived, energy efficient and allow for infinite on/off switching. This allows solutions to be smaller, battery powered, portable and with instant full light output.

What other technologies are currently in use?

Mercury based UV lamps have a filling composed of mercury and a starting gas usually Argon. There are two major types differentiated by the mercury vapor pressure in the lamp. Low-pressure lamps emit at a wavelength of 253.7nm. High pressure lamps radiate a broad-band UVC radiation, rather than a single bandwidth. The issue with UVC Mercury lamps is their size, toxic mercury usage, and need for chlorine to enable effective disinfection.

Excimer lamps produce UV light by spontaneous emission of Excimer molecules. Excimer lamps are mercury-free, instant on lamps which generate low levels of heat in comparison to mercury lamps. However, Excimer lamps have a low UVC efficiency and high cost.

What are the advantages of using LEDs for disinfection versus the other technologies identified?

- LEDs are environmentally friendly. They produce no Ozone.

- UV LEDs can be manufactured to operate at the optimum wavelength for the application: 265nm is widely recognized as the peak absorption of DNA; however, SETi has demonstrated that the peak disinfection efficacy of E.coli in water occurs at 275nm.

- Instant on/off and pulsing possible

- Compact form factor

- Low power consumption

Does UV light damage food?

No, in fact UV can be beneficial to food processing, production and help with maintaining freshness. Fresh food products are often processed using UV light to reduce the microbial load. Water has been treated with UV light to obtain drinking water for quite some time.

Ref. Hinds LM, O’Donnell CP, Akhter M, Tiwari BK. Principles and mechanisms of ultraviolet light emitting diode technology for food industry applications. Innov Food Sci Emerg Technol. 2019;56(January):102153. doi:10.1016/j.ifset.2019.04.006

Measuring disinfection

The degree of disinfection is directly related to the UV Energy density (or dose) applied. The amount of UV Dose depends on the intensity of light and amount of time light is applied. There are actually six levels of disinfection or effectiveness. The levels are based on the reduction factor; see table. If log reduction is measured directly after exposure, colony numbers will be low. However, it is important to re-count colony numbers after a period of time to see if any organisms reproduce after exposure. The United States Environmental Protection Agency (USEPA) lays down guidelines that state the minimum log reduction for commercial disinfection systems

Ref: Ultraviolet disinfection guidance manual for the final long term 2 enhanced surface water treatment rule, United States EPA, November 2006

Log Reduction Reduction Number of Bacteria left from a colony of 1 million 1 90% 100,000 2 99% 10,000 3 99.9% 1000 4 99.99% 100 5 99.999% 10 6 99.9999% 1 Table Log reduction

What are the best wavelengths for UV disinfection?

A wavelength of 265nm is considered the optimum as it is the peak of the DNA absorption curve. UVC has been shown to be effective in the disinfection of water, air, and surfaces on various pathogens such as E. coli, L. innocua, and COVID-19. However, disinfection and sterilisation occur over a range of wavelengths and in certain applications alternative wavelengths should not be dismissed. UVC LEDs can be manufactured to target very specific and narrow wavelengths. This allows solutions to be tailored to the particular application need.

Inside the semiconductor material of the LED, the electrons and holes are contained within energy bands. The separation of the bands determines the energy of the photons (light particles) that are emitted by the LED. The photon energy determines the wavelength of the emitted light, and hence its color. Different semiconductor materials with different bandgaps produce different colors of light. One the advantages of LEDs over Hg lamps is the precise wavelength (color) can be tuned by altering the composition of the light-emitting, or active, region.

How does UV-C Disinfection work?

UV based Disinfection (often termed as Ultraviolet germicidal irradiation or UVGI) is the use of ultraviolet (UV) energy (electromagnetic radiation with a wavelength shorter than that of visible light) to kill or inactivate viral, bacterial, and fungal species. Different wavelengths of UV in the range of 200nm to 300nm are absorbed by DNA, RNA and proteins. When UV light is incident upon the target source the incident photons are absorbed by DNA or RNA and cause inactivation of the DNA or RNA double helix strands through the formation of molecular lesions. If enough of these lesions are created, the replication process is disrupted, and the cell cannot reproduce. Also, absorption by proteins can lead to the breakdown of organism’s cell walls causing the cell to die. For most applications, replication prevention is sufficient. The UV doses required to prevent replication are much lower than required to kill, making the cost of UV treatment to prevent infection commercially viable.

Is UV-C light harmful? / Are UVC LEDs safe?

UVC lamps have been used for many decades to sanitize water, air and surfaces. However, precautions must be taken with this technology. Working unprotected for even a few minutes can cause injury.

UVC light is invisible to the human eye so during operation the light can be mistaken for being benign causing eye damage. As negligible heat is produced by UVC LEDs the user may not realize the danger until after the exposure has caused damage to the skin. Symptoms typically occur 4 to 24 hours after exposure. More serious effects of UVC include accelerated skin aging and skin cancer.

Traditional UVC lamps shorter than 250nm produce ozone which is emitted into the environment and needs to have appropriate infrastructure to remove. Some UVC lamps are made using mercury so safe disposal is essential. UVC LEDs do not emit ozone or contain mercury.

Does Each LED emit only a single wavelength?

No light source has a single wavelength. Light sources have a bandwidth. The wavelength used by LED manufacturers or LED Lamp manufacturers is based on the LED’s peak wavelength. This is the wavelength at which the source emits the most power. Ideally, all the light emitted from an LED would be at the peak wavelength, but in practice the light is emitted in a range of wavelengths centered at the peak wavelength. This range is called the spectral width of the source. The light output of a typical LED has a narrow spectral bandwidth from +/- 10nm to +/- 30nm. Reputable LED Lamp manufacturer’s datasheets will include this information.

Are 220nm LEDs available?

220nm LEDs are not commercially available right now. UV-C LEDs are a relatively new technology. The lowest wavelength available to buy is 255nm. However, UVC LED technology is rapidly developing and overtime new wavelengths will be developed, costs will reduce and efficiencies will increase as has already happened within the visible, infrared, violet and UVA and B wavelength LED ranges.

What is UV light and the range of UV LEDs?

Ultraviolet light (UV) is in the range of 200-395nm and are of three types: UVA, UV-B and UVC. UV-C is the UV range of 200-280nm. Typical UVC LEDs in the market emit at 255, 265, 270 and 285nms. While UV-A is now being used in curing applications effectively, UVC LEDs are now starting to be commercialised for applications cleaning, disinfection and sterilising applications.

What are UV-C LEDs?

A UVC light-emitting diode (LED) works like any other LED. It is a semiconductor device that emits light when an electric current is passed through it. Light is produced when the particles that carry the current (known as electrons and holes) combine together within the semiconductor material. Since light is generated within the solid semiconductor material, LEDs are described as solid-state devices. It distinguishes LEDs from other sources that use heated filaments (incandescent and tungsten halogen lamps) or gas discharge (mercury lamps).

The UVC wavelength band is defined as being in the range 200-280nm. Currently LEDs are commercially available between 255nm to 280nm.

UV LED Curing FAQ's

What is UV LED Curing?

UV LED Curing is a photopolymerization process in which UV energy is used to change a liquid to a solid. LED Technology provides significant advantages in UV Curing applications. Learn more about the Benefits of UV LED Curing vs. Traditional Systems.

What are the applications of UV LED Curing Systems?

UV LED curing systems are now the technology of choice across a wide range of applications including:

- Printing

- Industrial Printing

- Digital Printing

- 3D Printing

- Coatings Applications

- Adhesives

What are the Advantages of UV LED Curing Systems?

UV LED curing systems with no ozone emissions or mercury content provide a more sustainable solution than traditional technologies and offer many advantages such as:

- Vastly Improved Lifetimes

- Reduced Maintainence Costs

- Instant on-off

- Reduced Downtime

- Precise Light Control

- Significant Energy Savings

- In addition, the “cold cure” offered by LED-based systems is ideal for heat-sensitive substrates or thin films.

Download our whitepaper to learn more about Advantages of UV LED Curing Systems.

Laser Diode FAQs

What is a Laser Diode?

A laser diode is type of light emitting diode (LED). It is a semiconductor device which includes two different semiconductor materials, with an interface between them. When electrical current is applied, coherent light of the same phase and wavelength is emitted from the interface. For more information on Laser Diodes, see our laser diodes blog posts.

What are Laser Diodes used for?

Laser diodes are used in a broad range of applications including:

• Medical, biomedical and dental equipment for surgery, patient alignment, sample analysis and image capture

• Robotics and gesture recognition for factory and warehouse automation, autonomous vehicles, gaming and eye tracking

• Alignment and targeting in industrial, security and defence applications

• Measurement and 3D imaging for the construction industry, surveying, quality assurance in manufacturing, and profilometry

• Materials sorting applications in agriculture, food processing and waste sorting

• Laser shows and laser displays for the entertainment and advertising industries

• Laboratory analysis and smoke detection systems using particle measurement and spectroscopyFor more information on Laser Diodes, see our laser diodes blog posts.

Wavelengths and Colors of Laser Diodes

ProPhotonix offers laser diodes with a wide range of wavelengths and power outputs with many laser diodes in stock. We offer laser diodes from a range of high-quality manufacturers in

• Red Laser Diodes

• Green Laser Diodes

• Blue Laser Diodes

• Violet Laser Diodes

• IR Laser Diodes

Need help to optimize for your application?

For comprehensive technical support. Talk to us.

Contact UsContact Us

Bernhard Russell

Inside Sales

Andrea Gregorio

Inside Sales