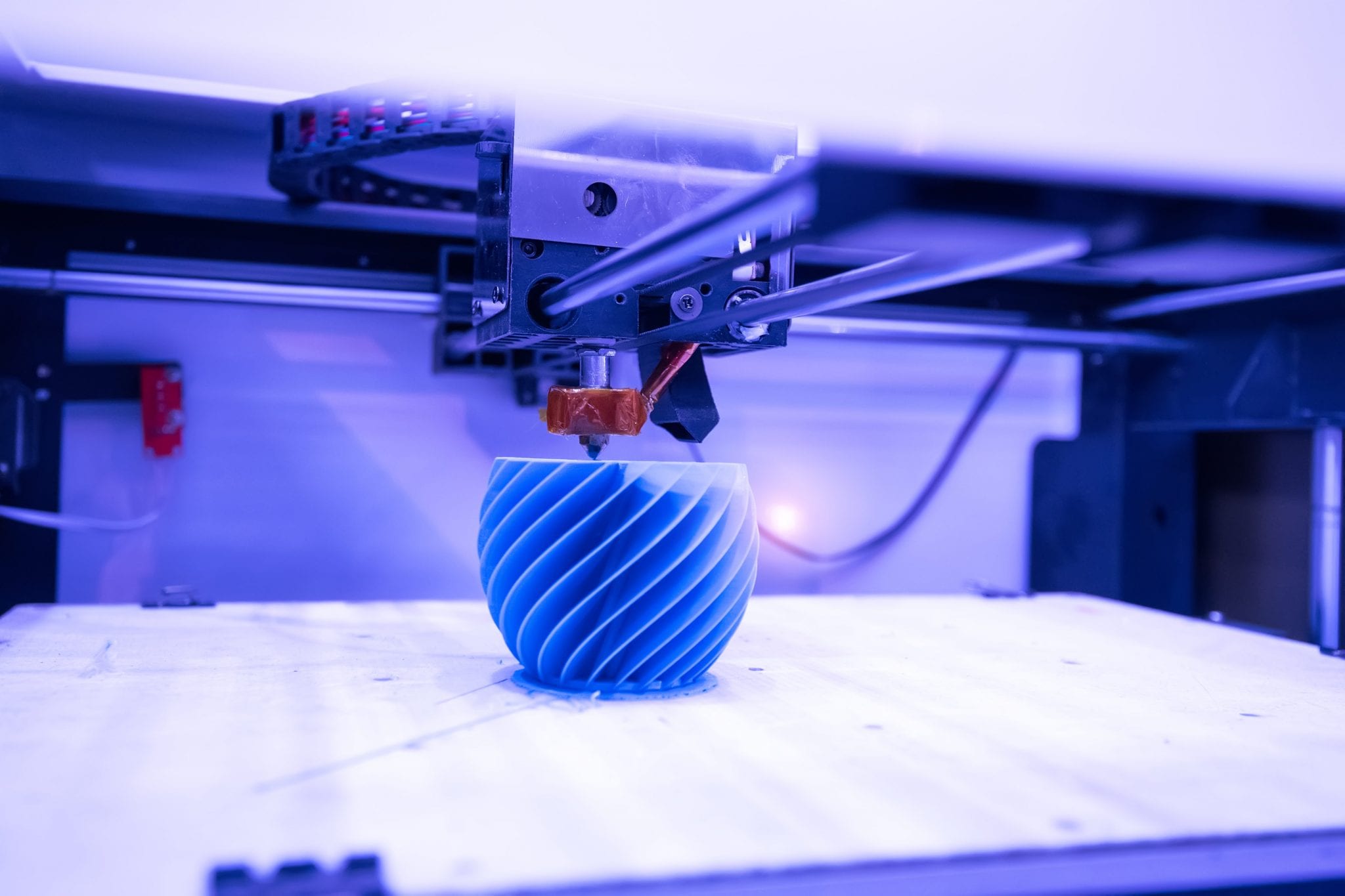

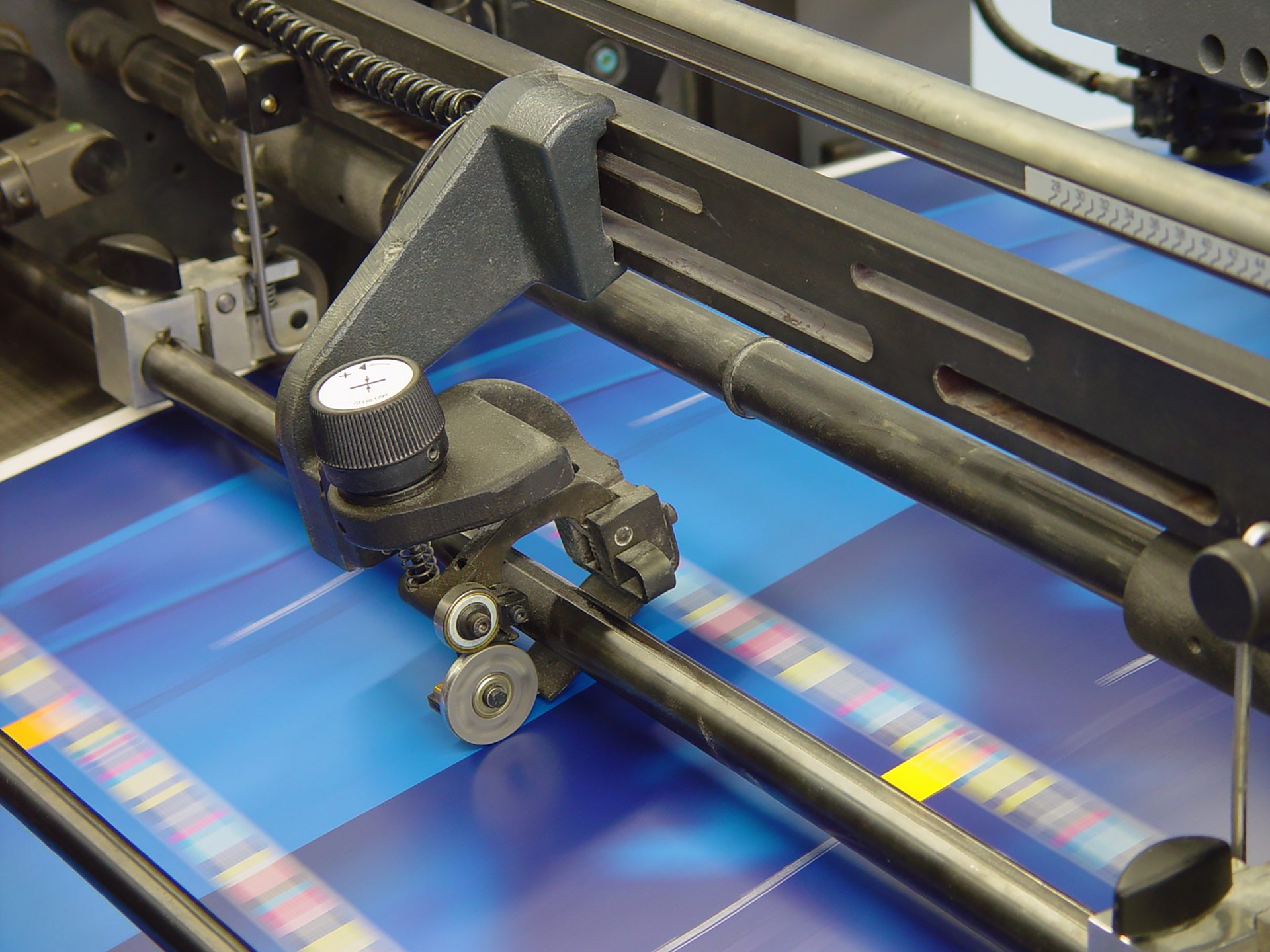

UV curing is a photopolymerization process in which UV energy is used to solidify liquids. UV LED curing systems are now the technology of choice across a wide range of applications including printing, 3D printing, coatings, and adhesives due to the inherent value of an LED solution. They offer vastly improved lifetimes, reduced maintenance costs, significant energy savings, and with no ozone emissions or mercury content, offer more benefits than traditional technologies. In addition, the “cold cure” offered by LED-based systems is ideal for heat-sensitive substrates or thin films.

Reliable Performance, Lower Cost of Ownership

UV LED Curing Systems

UV LED Curing Systems: Cobra Cure FX Series

The COBRA Cure FX series is designed to provide the optimum UV curing of inks, coatings, and adhesives. In addition to the many benefits of an LED UV curing light solution, these lamps incorporate unique patented features to ensure a consistent, reliable cure. Each UV LED lamp is configurable to your application requirements with mechanical, optical, and electronic options available. The COBRA Cure FX Series encompasses 15 years of experience in UV LEDs and more than two decades of experience working with OEMs to maximize system performance.

COBRA Cure Series:

New COBRA Cure Mini

6W/cm² Compact, Light form factor UV LED curing system offers a cost-effective solution for high-speed single and multi-pass printers.

View Details

COBRA Cure FX1

5.4W/cm² Compact, UV LED curing system offering a stable, reliable cure over a long lifetime, ideal for printing and 3D printing applications.

View Details

COBRA Cure FX1 Max

6.4W/cm² UV LED curing system has 20% higher intensity than the COBRA Cure FX1, well suited for limited space applications requiring higher intensity and dose.

View Details

COBRA CURE FX2

8.4W/cm² UV LED curing system is a compact, fan-cooled system offering excellent intensity control across varying conditions to ensure an even cure.

View Details

COBRA CURE FX3

20W/cm² UV LED curing system offers industry-leading intensity and dose values and edge to edge illumination, ideal for UV curing of inks, coatings and adhesives.

View Details

COBRA CURE FX4

14W/cm², 58J/cm² UV LED curing system with high-density Chip-on-Board LED arrays and a wide 40mm window, ideal for large format, high speed printing.

View Details

UV LED Curing Systems Advantages

The emerging UV LED market is leveraging all the expertise and supply chains built up within the wider LED industry to ensure a high-performing reliable solution. Selecting the best UV LED curing lamp, the optimum wavelength, and utilizing the correct curable media will improve cure quality, increase throughput and deliver consistent performance over time.

Download our whitepaper to learn about the advantages of UV LED systems versus traditional technologies for the curing of inks, coatings, and adhesives.

UV LED Curing Systems Features

The COBRA Cure FX series is a configurable platform designed to maximize the inherent value of LED solutions while also incorporating a number of unique features. These patented features have been developed to ensure ease of integration, optimum performance, maximum lifetime, safety and reliability in the field.

The platform can be configured to address a wide range of user requirements including optimized optics, customizable mechanics and electronic options. Users will benefit from innovative features, including a field-replaceable window, designed to allow rapid replacement of windows with a build-up of ink mist, without the need for any special tools.

Whitepaper

Specifying UV LED Curing Systems

Understanding the technical and commercial considerations can help you to specify the optimum UV LED Curing system for your application. For optimal curing, key considerations include wavelength selection, light output profile, working distance, intensity and dose requirements, and uniformity. This whitepaper outlines key considerations to optimize curing, form factor and control requirements, system validation, reliability and cost of ownership.

Need help to optimize for your application?

For comprehensive technical support. Talk to us.

Contact UsContact Us

Bernhard Russell

Inside Sales

Andrea Gregorio

Inside Sales

UV Curing Resources:

Specifying UV LED Curing Systems

Outline of the key considerations to optimize your UV LED Curing Systems.

Download »

New Whitepaper: Irradiance and Energy Density in UV Curing Applications

A discussion of these two key UV lamp characteristics to ensure you achieve the optimal cure in your application.

Download »

UV Curing Blog Posts

Key considerations in UV Curing Lamp Selection, The Benefits of UV LED Systems....

Learn More »

Market leading product performance

UV LED Curing Systems are designed and built to deliver maximum performance throughout the lifetime of the products.

Flexibility to adapt to your needs

Flexibility to configure or customize your product to your application requirements and flexible ongoing support to meet your business needs.

A complete solution provider

We take a long term view of customer relationships supporting you from concept to completion as well as with day to day business needs.