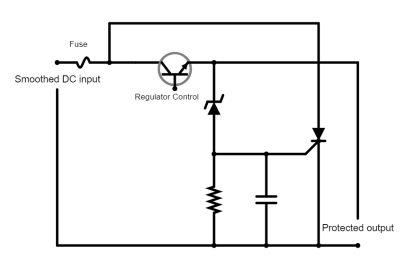

From industrial to medical and dental, to scientific and 3D printing, many applications today need high-quality precision laser modules to perform a variety of tasks ranging from alignment and guidance to 3D measurement and analysis. Due to the unique nature of each application, not all system requirements can be met using an off-the-shelf laser solution. For these instances, the ProPhotonix team partners with customers to design and manufacture custom laser diode-based solutions that address challenging application-specific requirements for wavelength, beam properties, output power, lifetime, form factor, and others.

As a laser diode distributor and a laser integrator with in-house engineering and manufacturing capabilities, we offer customers a unique combination of design expertise, strong supplier partnerships, and ongoing engineer-to-engineer support. Additionally, with more than 25 years’ experience developing OEM laser solutions, we accelerate time to market by leveraging our extensive “design bank.” We also utilize our well-established relationships with engineers and R&D staff at the major laser diode manufacturers to gain early access to new technologies. As a result, we offer our customers a competitive edge by delivering reliable, high-quality, cost-effective OEM laser modules fast.