Industry: Textile Recycling

Solution: COBRA HyperSpec SWIR

Customer Requirements

By 2025, the EU will require that all member states separate their textile waste in an attempt to increase textile reuse and recycling1. This raises a number of questions: how do you differentiate between different colors of the same material type, different material types, and blends of materials? Vision systems are well placed to address the challenges that these requirements present and the use of hyperspectral imaging has proven to be invaluable to the identification of specific materials.

ProPhotonix recently worked with a customer manufacturing textile recycling machines providing a COBRA HyperSpec SWIR for their vision system. This case study will detail the application requirements and the solution provided.

The customer required a lighting solution that would allow them to sort textiles according to the type of textile as well as the color of the material.

Infrared and SWIR hyperspectral imaging for Material Sorting

In textile recycling, three broad categories exist: textiles encompassing man-made, plant-based, and animal-based fibers. The use of hyperspectral wavelength bands, and the varying spectral response to these wavelengths from each of the material types, can be used for differentiation.

The response curve of a reflectance spectrum can highlight many features unique to specific fibers, whether they are manmade, plant-based or animal-based fibers. For example, polyester is known to have a significant drop in reflectance in the SWIR region of ~1650nm, whereas all other fibers exhibit full reflectance in this region. This wavelength, therefore, is an important tool in sorting out polyester-type textiles.

Similarly, plant- and animal-based fibers exhibit a drop in reflectance between 1400 – 1600nm, however, there is no drop in reflectance for the manmade fibers, acrylic and polyester. Therefore, to separate these from animal, and plant-based fibers, you would focus on the 1500nm to try to filter out the two.

In addition to identifying various textiles, textile types as well as colors, there may also be mixes of textiles. It’s not only the SWIR band that can be used for textile recycling. You can also use a visible IR band.

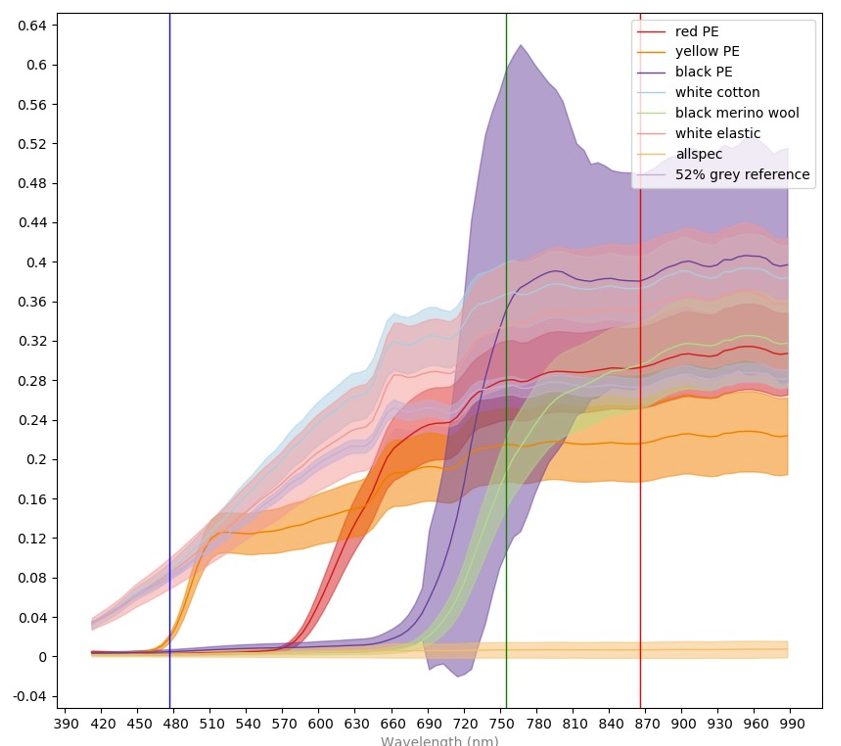

The chart above shows the spectral response of different materials between the 400 and 1000nm band. Here we see the reflectance spectra for a variety of different material colors and types, such as Polyethylene, Cotton and Merino. On the top-right, you see the various material types being analyzed: polyethylene, cotton, merino, and an elastic mixture.

In this example, a solution for textile recycling would be both visible IR as well as SWIR. In this particular case, you can see that the yellow polyethylene, the red polyethylene, and the black polyethylene, have the same shape curve but their onset point is different. They exhibit a very similar spectral response but the onset point is dependent on the color of the material being imaged. The cotton, however, exhibits a different shaped curve to the PE. Employing various algorithms will allow the imaging system to differentiate between material types and colors.

This response is how we differentiate between material types using either SWIR or visible IR hyperspectral imaging. The same technique is often employed when using the hyperspectral band 400nm to 1000nm

The bottom line, is that the customer now has an effective means for sorting recyclable materials quickly and efficiently.

The Solution: Hyperspectral LED Line Light

SWIR and Infrared illumination offer a cost-effective and sustainable solution to aid the separation of different textiles and improves the effectiveness and detection capability of vision systems.

COBRA HyperSpec from ProPhotonix offers hyperspectral tunable illumination for optimal image acquisition. Discrete control of up to 12 different wavelengths allows for the creation of a broad spectrum with excellent uniformity and high-quality imaging. Now configurable in the SWIR range, the COBRA HyperSpec offers high resolution illumination across a broad spectrum by utilizing customizable chip-on-board technology. LEDs can be boosted at any wavelength to optimize for any application. Via an intuitive GUI, users can discretely control up to twelve different wavelengths. This allows for balancing intensities, matching a camera’s sensitivity curve or countering for light deficiencies with a camera sensor thus providing a continuous broad spectrum.

1 EU Directive (WFD, Article 12b DIRECTIVE (EU) 2018/851), (https://bit.ly/3vS2Rzv)