The term “high performance laser” is often considered as being synonymous with “high power laser”. However, when specifying a high-performance laser, it’s important to take additional factors into consideration. A high-performance laser module should meet or exceed a number of other criteria including reliability, wavelength, how easily it integrates with your systems and output stability (even under challenging operating environments).

Here are some of aspects of a high-performance laser worth considering:

Reliable High-Power Laser Module

Where high output is required, a reliable laser with a stable, precise and consistent beam is critical. Changes in temperature (as a result of environmental conditions or heat generated by operating the laser) can jeopardize these and lead to drop in power, drifting wavelength or mode hopping affecting the beam profile and output.

Temperature can also impact your laser’s performance in more subtle ways. Lenses and other optical components can contract or expand slightly with changes in temperature. While these changes can be small, they will have a considerable impact on beam quality and the reliability of your laser.

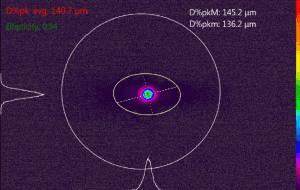

Laser Beam Characterization

High Stability Optical Output

Managing the temperature of your laser module will be key to ensuring high stability optical output. The kind of thermal management selected by the manufacturer will depend on factors such as the operating environment, your application and overall budget. Options can include passive devices such as a heatsink or active devices such as a TEC (thermo-electric cooler).

The laser module’s temperature is determined by the ambient temperature and the electrical power dissipated by the laser during operation. Heat can build up in each component and leak to cooler surroundings, potentially damaging critical components, if there is no thermal resistance built in.

PROdigii Digital Laser Modules Range

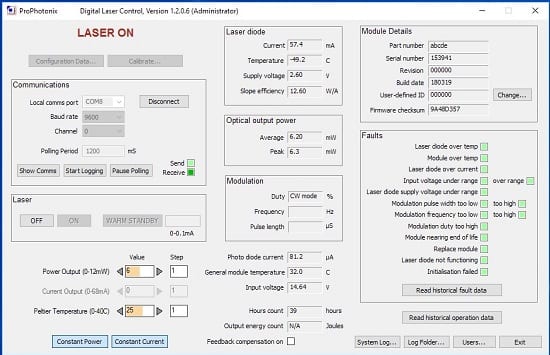

Digital Control for Optimized Laser Performance

If your application requires a high-performance laser, then being able to control and monitor laser performance and precision is essential. A digital interface can offer a variety of functions from a simple on/off function to operating the laser performance (for example, output power and operation mode). Digital interfaces can vary in functionality so the degree of sophistication required will depend on your application.

PROdigii Digital Laser Interface

PROdigii Digital Laser Interface

What can High-Performance Lasers Accomplish?

ProPhotonix recently developed the PROdigii laser for an advanced wheel monitoring system for use in a rail inspection system. PROdigii is a robust, reliable high-performance laser module that delivers even in challenging operating environments. The wheel monitoring application required a high uniformity IR laser that operated consistently in real time. The considerations discussed above were critical to delivering a high-performance laser module. Thermal management allowed for the laser to operate in all kinds of weather conditions while the GUI digital interface allowed for remote operation and real time analytics.