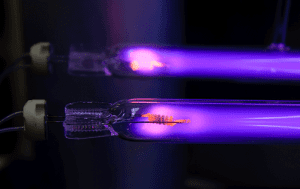

Interest in UVC LED technology continues to grow due to the inherent advantages of LED technology and significant advances in the development of UVC LEDs. Recent studies showing the effectiveness of UVC light in disinfecting COVID-19 have further increased the relevance of this technology.

This post will provide an overview of UVC LED technology, describing how UVC light is used in disinfection applications, which wavelength is optimal, a discussion of the safety precautions required with UV light, and a comparison of UVC LED lamps versus the traditional UVC mercury lamps.

What is UVC?

Ultraviolet is the invisible range of light spectrum from 200-395nm. UV light is further categorized as UVA, UVB, and UVC. The specific wavelength range for UVC is 200-280nm. This range of light is commonly used for disinfection applications.

How Does UVC LED Technology Work?

In this type of disinfection, also known as ultraviolet germicidal irradiation (UVGI), the DNA, RNA, and proteins of the organism absorb the UV light. This causes the inactivation of the DNA or RNA double helix strands, which leads to the interruption of the cells’ replication process. Once the cells are no longer replicating, they are no longer infecting. UVGI only requires enough light to halt replication, which is significantly lower than the amount needed to kill.

UVC Wavelengths

As mentioned, the spectrum of UV light is defined as that between 200-280nm. For a UV disinfection application, the optimal wavelength is 265nm, which is the peak of the DNA absorption curve. UVC LED technology is still developing, however, which means that more wavelengths will become available and the efficiency of LEDs will increase. As this technology develops, costs will also continue to decrease which will make UVC LED a viable solution for an ever-increasing range of applications.

Is UVC Safe?

UVC light has already been used for decades for disinfection applications, but certain precautions need to be taken when using UV lamps. UV light is not visible to the naked eye and can cause damage to the eyes and skin with prolonged exposure. Proper safety equipment, including safety goggles and ensuring exposed skin is covered, should be taken by the operators of UV lamps. It generally takes 4-24 hours for symptoms to develop after exposure, which can include redness of the skin. If eyes and skin are protected, UV light does not pose a harmful threat to operators.

UVC LED vs. Mercury Lamp

Mercury lamps were previously the only option for utilizing UVC light, but with recent technology advancements, LEDs are now commercially available in UVC wavelengths. When deciding whether to use a mercury lamp or LED lamp for your UVC application, there are a few points to consider.

Some considerations are:

- Size – LED lamps are smaller and more portable than mercury lamps

- Cost – Mercury lamps may offer a lower initial cost than LED lights but the total cost of ownership will be higher

- Environmental – Mercury lamps use toxic mercury and produce ozone. An optimized disinfection system with mercury lamps will also need chlorine to ensure effective disinfection. LED lamps do not contain mercury, emit ozone, or require chemicals to ensure effective disinfection

- Energy Efficiency – LED lamps are instant on/off, making them more energy-efficient than mercury lamps

UVC LED Technology Applications

UVC LED lights can be used in a number of water, surface, and air disinfection applications within the following industries:

- Food Processing

- Medical and Laboratory

- Packaging Materials

- Industrial Applications

As the technology continues to develop, new applications and innovative UVC LED solutions will continue to emerge.

ProPhotonix is a leading designer and manufacturer of Laser Diodes, Laser Modules, UV LED Curing Systems, LED Products, and UVC LED Disinfection Systems. Contact us for free expert advice on selecting the optimal solution for your system.