This post is the second in a series of tech notes examining laser beam properties. In this post, we will define pointing stability, discuss applications where this property may be particularly important, and highlight what a laser module manufacturer can do to control this property.

What is pointing stability?

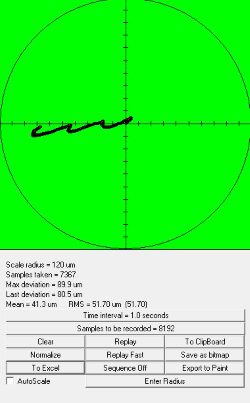

This laser property quantifies how much a laser beam drifts from the ideal target. Pointing stability can vary with both time and temperature. The pointing stability of a laser module is typically measured with a beam profiler and the property is typically expressed in milli- or microradians (mrad or μrad).

In what applications is pointing stability important?

Pointing stability will be particularly important in any precision alignment or targeting application. Because changes in temperature are the most likely cause of poor beam pointing stability, environmental conditions, such as variation in ambient temperature, as well as heat generated by high power laser diodes or other laser module components, must be managed.

Pointing stability control

Where pointing stability is critical to your application, laser module manufacturers can integrate thermal management into the laser module. An example of this is ProPhotonix’ PROdigii digital laser module which incorporates a Peltier thermo-electric cooling device to actively control the temperature of the laser module. ProPhotonix can also improve pointing stability through aspects of mechanical design improving geometrical stability with temperature. For example, selection of materials (metals and glasses) with low coefficient of thermal expansion, or the use of specific bonding and assembly techniques.

With more than two decades of experience in designing and manufacturing laser modules for a wide range of applications, ProPhotonix is well placed to support you in selecting or developing the optimum laser module for your application. If you have an application requiring high pointing stability, contact us at sales@prophotonix.com

Sources: