When specifying laser modules for your application, one of the first optical considerations will be the wavelength and output power required for your application. These characteristics will determine the laser diode selected for your laser module. Once this is defined, other key optical aspects such as beam size and shape as well as working distance requirements will need to be specified to determine the best optical configuration for your laser module. In this extract from our latest laser module whitepaper, we’ll discuss laser beam shapes (collimated and focused beams), circular, elliptical and line lasers as well as laser beam size, beam waist and depth of focus.

Laser beam shape

TO-can laser diodes emit diverging elliptical beams. The difference in the divergence angles in the two directions perpendicular to the axis of propagation, (the axis along which the beam travels), and astigmatism (a difference in the apparent point source origin of the beam in those two dimensions) in the semiconductor diode chip results in a beam shape that is not only elliptical but changes with increasing distance from the laser diode.For almost every OEM application, this laser beam will need to be collimated or focussed.

Collimated Laser Beams

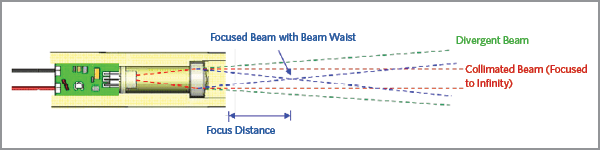

Some applications require a collimated laser beam. A perfectly collimated laser beam is the same size regardless of distance from the point of emission from the laser module. In reality, the laser beam will increase in size to some extent with distance from the laser module. The rate of increase in the beam size with distance is a measure of how well collimated the beam is.

Laser Beam Size

Other applications will require the smallest possible beam size at a specific working distance requiring an optical design to focus the beam. Optics will be selected to provide the required beam diameter at this “beam waist”. The beam will converge between the laser module and the beam waist, and diverge again after it. The extent to which the beam maintains the same size either side of the beam waist is described as its depth of focus. A greater depth of focus will provide a wider range of working distances.

When selecting the optimum laser module for your application, there will be trade-offs between beam waist, depth of focus and cost. With a simple, low-cost optical design a smaller diameter beam at the beam waist will have a shorter depth of focus and vice versa. More complex optical designs using two or more lenses will enable more precise control of beam size and degree of collimation.

Circular Laser Beams

As previously stated, most laser diodes will output an elliptical laser beam. Correcting optics can be used to make the beam more circular but there is a cost and loss of optical output power as a result of the additional optics. For most applications, an un-circularised, elliptical beam is satisfactory and more economical.

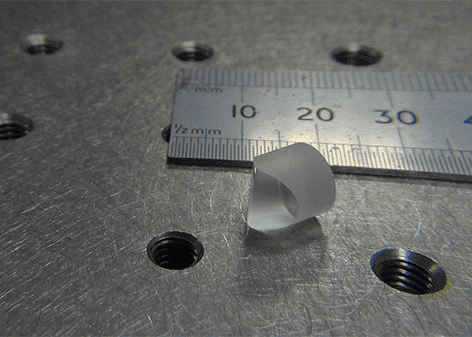

Laser Line Generators

When converting an elliptical beam laser to a line generator, the most suitable method will depend on the quality of the line needed for the application. A cylindrical line-generating lens will produce a line that is brighter and thicker at the center, tapering towards the ends with a Gaussian intensity distribution. This line is likely to be perfectly suitable for many visual alignment applications.

Learn more with our Successful Laser Module Specification Whitepaper

Optical design is a critical element of laser module specification. Other elements including thermal management, mechanical aspects, and electronics also provide opportunities to maximize the performance of your laser module. To learn more about specifying laser modules for your application, download the latest whitepaper from the experts at ProPhotonix. In “Successful Laser Module Specification”, ProPhotonix’ laser engineers, provide an expert guide, highlighting key criteria and trade-offs to ensure successful specification. Providing application-optimized laser modules for more than 25 years, ProPhotonix has developed a 7-element approach to successful laser module specification.

The “Successful Laser Module Specification” Whitepaper details:

- Wavelength Selection

- Output Power Considerations

- Optical Design

- Thermal Management

- Mechanical Aspects

- Drive Electronics

- Partner selection