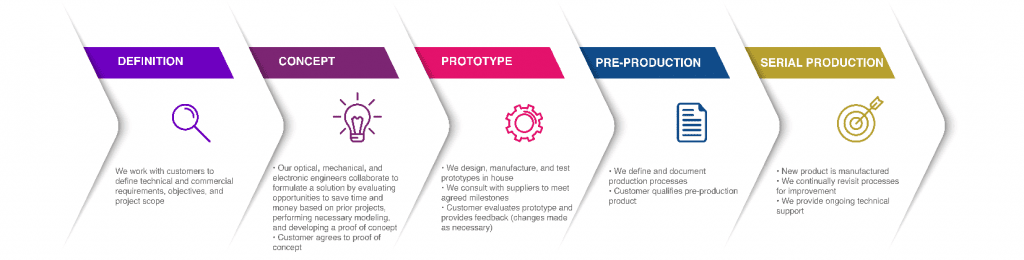

When an off-the-shelf LED solution or standard laser module cannot meet your specific application needs, you don’t just need a supplier that can tweak an existing product to create a “good enough” solution. Instead, you need a highly skilled team that will partner with you from specification development to postproduction to create a custom solution that will meet your specific needs and budget. At ProPhotonix, our engineers achieve this by partnering with customers to define, refine, develop, and produce the right LED solution or laser module tailored to your unique application – all in house. The graphic below provides a brief overview of our partnership approach to custom development, but let’s explore these five stages in more detail.

ProPhotonix – Your Partner from Specification Definition to Postproduction

At the beginning of each custom engagement, our engineering team works directly with the customer’s engineers and project managers to define technical and commercial requirements and objectives. Often customers need help defining elements of the specification or clarification that the specification is achievable. By working hand-in-hand, we ensure the correct project scope and specifications are developed. Once these are agreed upon, our multi-disciplinary team of engineers collaborates to develop the product concept. To save customers time and money, where possible, we can turn to our extensive “design bank” to leverage our knowledge base from prior projects. Taking an existing design, we perform the necessary modeling and iterations to develop a proof of concept for the customer to approve before we start work on the fully specified prototype.

Since we develop our prototypes in-house, we can manage a dynamic design, manufacture, and test process where customers are informed on and involved with each step. Once the prototype is signed-off by the customer, we move into pre-production. At this point, we define and document the entire production process in addition to finalizing the pre-production product with the customer before moving to serial production.

Beyond our defined design and development approach, there are a couple other unique aspects of our process that set us apart from our competitors. First, we work closely with our supply chain partners and we manufacture many critical parts to ensure reliable supply and a quick turnaround at each stage of the development process. Additionally, we manufacture all our prototypes and custom illumination solutions at our ISO-certified production facilities. This means we can produce a wide variety of systems, including those that are complex and powerful, in both low and high volumes. Finally, we don’t let our customer partnerships end when a product ships. Instead, form long-term relationships with customers that includes responsive technical support throughout production and through to progressive generations of products.

Experience the Benefits of Our Well-Established Supplier Partnerships

Our partnership approach is not exclusive to our relationships with our customers. Our ability to successfully and cost-effectively design and manufacture custom LED solutions and OEM laser modules also depends on the partnerships we’ve established with a variety of key suppliers over the past two decades. This means we are confident we can depend on each one of our suppliers to uphold their delivery commitments, which means we can stick to our timelines.

More specifically, on the laser side of our business, our laser design and manufacturing teams work closely with suppliers of key components such as laser diodes and lenses. As a result, we can offer customers unique benefits such as early access to new laser diodes and more detailed technical information on specific laser diode performance aspects to guarantee we select the best diode to meet your application needs. On the LED side, the strong relationships we’ve formed with suppliers means we are always up to date with the latest LED technologies, can source LED chips at competitive prices, and can deliver prototypes quickly.

Meet Your Specific Illumination Needs by Partnering with ProPhotonix

Our application-centered design approach based on forging strong customer relationships during the design process helps us understand the unique environmental and application-specific needs of our customers, which ultimately leads to better solutions. Combined with our established supplier partnerships, we have the unique ability to efficiently develop custom illumination solutions optimized to meet application-specific needs, on budget and on time.

Learn more about our approach and the technologies we use to develop custom LED solutions and OEM laser modules.