In this post, part of our series on Machine Vision Lighting FAQs, we’ll look at an important consideration which is all too often overlooked until late in the design of vision systems; that of form factor in Machine vision lighting.

Why is form factor important?

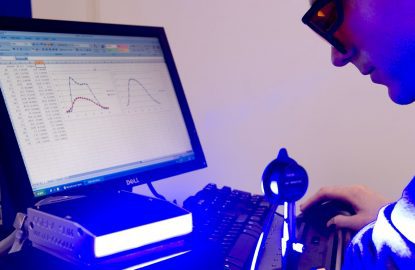

This may seem obvious but without the optimum form factor your vision system will not perform as well as it could. It’s worth remembering that the form factor of your machine vision lighting has an impact not only on the size of the overall system, which can be a limiting factor in the success of the project, but also on the performance of the system. Why? The angle of your illumination is critical to optimizing your machine vision system and in systems where the illumination is not considered early enough in the design process, compromises may have to be made. These compromises, either in terms of your lighting choice or your lighting angle have the potential to significantly impact on the performance of your system.

Selecting the optimum machine vision lighting

ProPhotonix offer some of the most compact illuminators on the market. Due to our expertise in Chip-on-Board Technology and optical design, our products also offer market leading intensity and uniformity, ensuring the optimum image quality is delivered to your system. We also offer some of the most flexible products on the market. Our COBRA Flex series, for example, is designed to offer the performance of the COBRA Slim Series in a flexible form factor. The compact light head can be installed in tight spaces with the electronics housed separately. A number of mounting options are also available.

Specific Application requirements

If you have an machine vision lighting application with tight space constraints, contact one of our applications engineers at sales@prophotonix.com for advice on how to optimize your vision system with Machine Vision Lighting.