Line scan systems utilizing LED line lights are used for sorting and grading of solar cells to increase throughput and reduce costs for solar cell production. As solar panels require different cells to work together, vision systems are used to accurately detect defects early to avoid whole modules being compromised.

Wafer Inspection

Inspection of solar cells provides challenges for illumination because the materials being inspected are designed to absorb light and the surfaces are highly reflective. LED line lights in the IR and UV ranges are extremely useful in this industry. IR illumination penetrates silicon allowing micro-cracks below the surface to be detected. UV lighting is ideal for solar cell inspection as it reflects well in spite of the anti-reflective coatings on the cells. Red, White and other wavelengths are also used in this industry depending on what is being inspected.

Silicon Wafer Inspection

The efficiency and optical yield of a solar cell can be significantly impacted by the presence of defects in the raw silicon material. These may include micro-cracks, saw marks, edge defects and inclusions. Machine aided vision systems are used to enhance quality standards in solar cell manufacturing systems, by detecting flaws in the raw silicon materials.

Back Light Solution

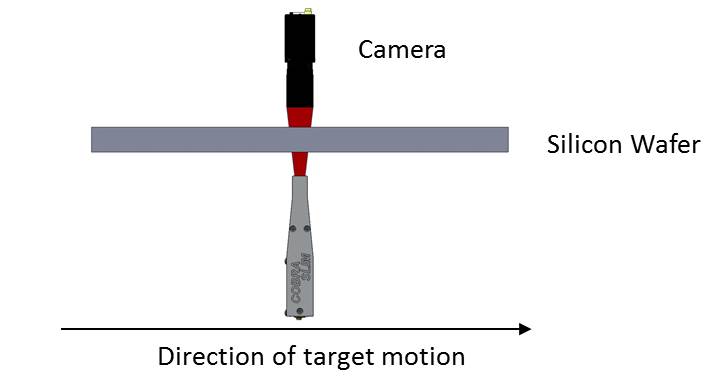

Defects in silicon wafers are most readily detected by illuminating the target from the rear and detecting the light transmitted through the wafer. This is commonly referred to as a backlit solution (Fig. 1). Using this method, defects in the silicon are manifested as dark spots or shadows in the transmitted beam.

Wavelength

In order to maximize power yield, solar cells are typically designed to be efficient absorbers of visible light. Backlit solutions cannot therefore utilize visible sources. Silicon wafers are however, transparent to infra-red, hence allowing the camera to look “through” the silicon wafer and inspect for defects and flaws.

Figure 1: Backlit illumination scheme: Light transmitted through the target is detected by the camera.

Conclusion

LED line lights used in silicon wafer inspection ensure quality and efficiency of the solar cells being manufactured. LED line lights provide the ideal solution due to the flexibility of wavelengths and backlight options available. ProPhotonix works directly with a number of large solar cell equipment manufacturers to deliver LED line light solutions for Silicon wafer inspection. To learn more, visit the LED Line Lights page.