Laser line generators are increasingly required in applications to replace traditional laser modules. In this post, we outline how ProPhotonix improved upon a customer’s legacy laser module in a system for precisely aligning large metal sheets.

Requirement

In this application, the laser line provides a guide for the customer’s employees to connect the various sheets of metal within tight tolerances. As a result, the application required a uniform line thickness and line straightness. The existing laser module solution did not adequately meet the customer’s requirements.

Challenge

The laser module, operating at 660nm wavelength, needed to project a laser line with a working distance between 18 to 1800 inches (450mm to 4600mm). Across this working distance, the laser line needed to remain in focus. The challenge: to build a module with a depth of focus of 197 inches (5000mm), and a line width uniformity of 0.08 inches (2mm) along the length of the line and the entire range of working distances. Finally, the line straightness could not deviate beyond 0.0083°.

Line Measurement Technique

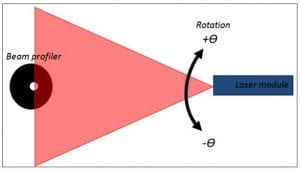

There are different methods of measuring line straightness in a laser. It was critical to develop a consistent and reliable line straightness measurement protocol between our engineers and our customer. A rotational technique, developed by ProPhotonix, accomplished the precise, accurate and reliable results across the long working distance.

Why Use Root Mean Square Value (RMS)?

If we sample the line thickness at tiny intervals we may get slightly different values. We use root mean square value to give us an average value over time. By squaring each value, adding up the square and dividing by the number of measurements we get the average square or mean square. Taking the square root of that gives us the “root mean square” (RMS) average value, a more accurate reflection of the beam width over time.

Results

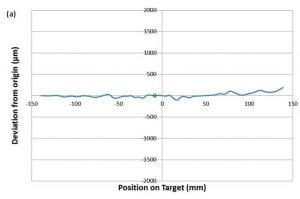

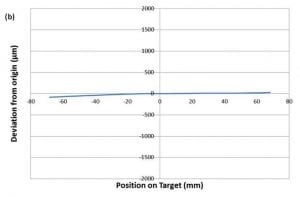

A baseline assessment of the legacy module with multiple line straightness measurements, taken at different working distances for the legacy module, provides the starting characteristic. Tests on the legacy module showed a line thickness RMS value of ~600µm, at 600mm working distance. This is equivalent to a line straightness of 5.4%. The profile across the projected laser line is neither symmetric or consistent . The test results on the ProPhotonix module gave an RMS value of 37µm at 600mm projection distance, equivalent to a straightness of 0.6%.

Figure 2. Graph showing a comparison of line straightness between the legacy module (a) and the 3D PRO (b) The legacy module has a line straightness value of 127µm. The 3D PRO has a line straightness value of 25.5µm.

Solution

Final results showed that the optimum solution to maximize depth of focus was to employ an AF version of our standard laser line generator module, where the apex of the line generating lens was precisely oriented to the longest axis of the elliptical beam. The results are a line straightness of 0.129%, versus the customer specification of 1% maximum.

To learn more about laser line generators from ProPhotonix, contact us.