In this post, we look at how Infrared LED Illuminators help one of the world’s largest glass container manufacturers guarantee the quality of their product.

Glass Bottle Inspection Requirements

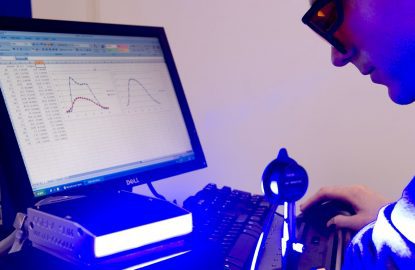

Requirements for glass bottle inspection applications differ significantly due to the variations in shape, color, opacity and design of the containers. To ensure the quality of the end product, a vision system is used to inspect every aspect of the bottles produced. Vision systems are also used at a later stage of the process to determine the fill level of the bottles.

The customer required a backlight illuminator, in the IR spectrum, that was compact, intense, and uniform with strobe capabilities.

Wavelength

The IR wavelength used in the vision system for this application allows the delivery of high quality images to identify defects in darker glass containers prior to filling. Infrared illumination penetrates the darker types of glass bottles that pass through this inspection point.

Intensity

One of the key challenges was to deliver intensity high enough to penetrate the glass to ensure that the vision system delivered a clear image. To meet this intensity requirement, a Chip-on-Board LED product was developed.

Size

The space designated for the infrared illuminator provided a number of constraints for designing the illumination. Chip-on-Board Technology, in combination with optical, thermal and mechanical design, presented the ideal solution to overcome this challenge.

Chip-on-Board technology resulted in the ability to offer the optimum solution for our customer. Our engineers worked with the customer identifying the ideal solution for their vision system to provide a variety of infrared products of differing wavelengths enabling them to perform necessary inspection.

To learn more about this application, download the case study.