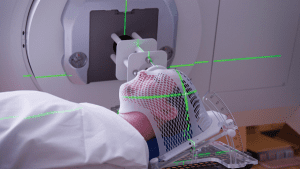

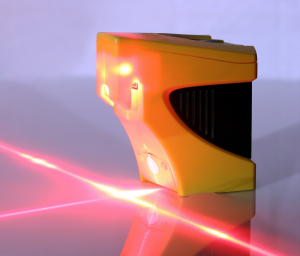

Crosshair lasers are essential tools for ensuring precise alignment in a variety of applications, from aligning logs in sawmills to positioning patients for X-rays. The right crosshair laser enhances both precision and efficiency, making it crucial to choose the appropriate one for your needs. This blog highlights key factors to consider when selecting a crosshair laser, helping you achieve the highest level of accuracy in your projects.

Key Factors to Consider

When selecting a crosshair laser, several key factors such as alignment accuracy, wavelength, working distance, fan angle, power output, and laser safety must be considered to ensure it meets your specific needs.

1. Accuracy and Precision

Cross lasers projecting thin lines have higher accuracy, in turn, allowing precise pointing of the beam and easier identification of the crosshair. High laser beam pointing accuracy is essential for applications with longer working distance while applications with shorter working distance may not require such precision. It is also important to select the right fan angle for different working distances.

2. Wavelength and Visibility

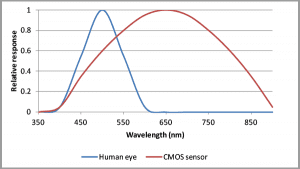

Crosshair lasers are commonly offered as red crosshair lasers or green crosshair lasers. Due to the shorter wavelength, green crosshair lasers are highly visible to the human eye and natural light. The visibility range of crosshair lasers is also dependent on the lighting conditions. For example, green crosshair lasers are visible up to a range of 100 feet even in bright lighting conditions.

3. Power Output and Eye Safety

When it comes to the power output of crosshair lasers, there are many factors to be considered, including working distance, lighting conditions and more. Red cross lasers require less battery power while green cross lasers often require more battery power. Additionally, laser safety is crucial when considering power, particularly when the beam may be used in close proximity to the human eye.

4. Durability and Build Quality

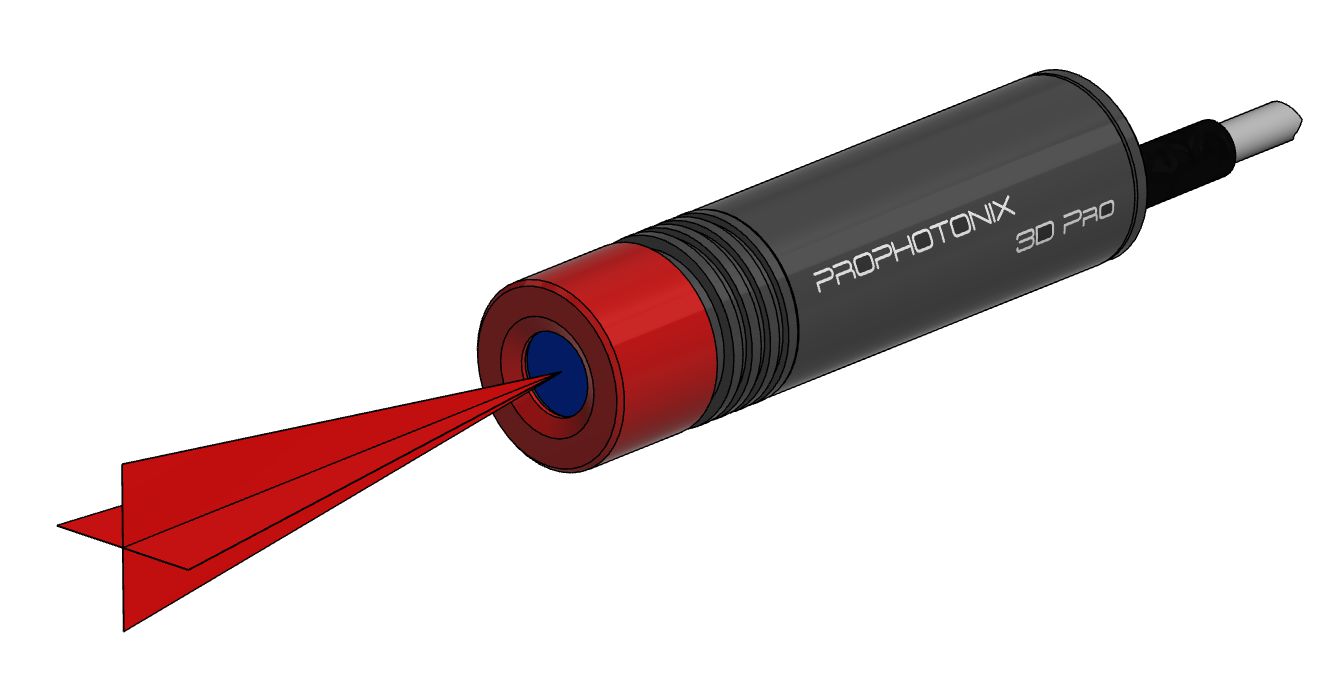

Before selecting a crosshair laser for your application, it is important to take note of the design of the laser module and how resistant it is to environmental factors such as heat, dust and moisture. ProPhotonix offers high-quality durable crosshair lasers with an IP67 rating for dust and water protection. Cross laser modules with excellent thermal management also have enhanced laser life.

5. Mounting and Adjustment Options

Finally, the availability of mechanical features for mounting and alignment, custom cables, and connectors can also affect the efficiency of a crosshair laser for specific applications. It is important to have the flexibility of alternative flange shape and size for easier installation and laser alignment. Consider whether the laser offers the following-

- Are there holes in the flange for mounting? Are these holes threaded or unthreaded?

- Are there any slots or markings for clamping and alignment?

6. Application-Specific Considerations

Crosshair lasers are utilized across a variety of industries, each with its own unique demands. Visit the blog post ‘Exploring the Applications of Cross Hair Lasers’ to learn more.

Tips for Selecting the Right Crosshair Laser

Here are some practical tips to guide you in selecting a crosshair laser that best suits your application requirements.

1. Assess Your Needs

Start by identifying the primary use case of a crosshair laser within your application. Once you have figured that out, based on the key factors listed above, make a list of high priority features for your application.

2. Consulting with Experts

If your application has specific needs, the best approach is to obtain expert advice from professionals. With over two decades of experience in laser module design and manufacture, ProPhotonix experts are well-placed to offer you the best advice for specifying a high-performance crosshair laser for your application. Get in touch with our experts here.

3. Testing and Prototyping

The value of hands-on testing and prototyping to ensure product fit cannot be overstated. At ProPhotonix, the configuration process involves collaborating with our customers to understand their application and specifications. This is followed by the development of the parts, the assembly, and thorough testing before delivering the final optimized laser solution.

Conclusion

By carefully considering factors such as accuracy, visibility, power output, durability, and industry-specific requirements, you can pick a crosshair laser that enhances your applications.

ProPhotonix offers a range of robust and highly precise crosshair laser modules with red, green and other wavelengths of cross laser line output. For advice from our laser module experts, email us at sales@prophotonix.com.

ProPhotonix is a leading designer and manufacturer of Laser Diodes, Laser Modules, UV LED Curing Systems, LED Products, and UVC LED Disinfection Systems. Contact us for free expert advice on selecting the optimal solution for your system.

ProPhotonix laser module range includes laser modules by beam shape including crosshair lasers, line lasers and dot laser modules. Contact us for free expert advice on selecting the optimal solution for your system.