Structured laser light (SLL) is a technique for projecting a known pattern of pixels (singular line, horizontal lines, crosshair, grid) onto an object. Vision systems calculate the depth and surface information of objects from the deformation of the light when it strikes the object’s surface. In machine vision, singular straight lines are the most common configuration. In this post, we look at the benefits of a Structured Light Laser versus a Laser Line Generator.

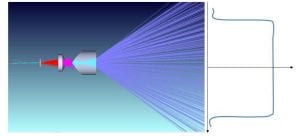

Laser Line Generator

A laser module which utilizes a cylindrical lens, known as a laser line generator, is sufficient for the majority of applications. A cylindrical lens produces a non-uniform, Gaussian laser profile with intense center area and fading edges along the projected line. Line modules utilizing these lenses are an easy and inexpensive solution but deficient in optical performance and uniformity.

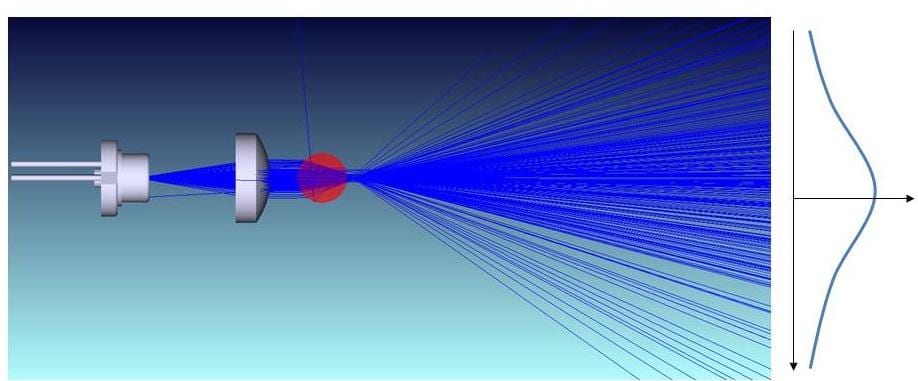

Structured Light Laser – Powell Lens

A laser module utilizing a Powell lens, often referred to as a structured light laser, is preferred for applications with more exacting requirements. A Powell lens resembles a round prism with a two-dimensional aspheric element on its apex. The output line from a Powell lenses is a uniform distribution of energy. This is achieved when the laser beam hits the apex causing spherical aberrations (imperfection of the produced image) within the lens redistributing the light such that it decreases the light in the central area of the line while increasing the light intensities at the ends of the line. The output is an optically efficient, uniform line.

Key Considerations

Beam Width

The powell lens performance is very sensitive to beam diameter. It is also wavelength dependent. To get an even distribution of energy, the apex curvature needs to be precisely optimized for a particular laser beam width.

Fan Angle

The fan angle of the output beam is dependent on the refractive index of the glass and the roof angle of the Powell lens. The steeper the roof and the higher the refractive index, the wider the fan angle and the longer the line of a given projection distance. In extreme fan angles (90° – 125°), the Powell lens is more difficult to manufacture and prone to unintended aberrations in the output beam. As a result of these manufacturing issues, structured light laser modules that incorporate Powell lens tend to more expensive than line generator modules but with a much better beam characteristic.

Powell Lens Configuration

The Powell lens has two configurations based on lens placement relative to the incoming laser beam. Powell lens positioning directly affects depth of focus and the thickness of the laser line. To achieve a narrow incident beam orientation, a thin laser line with a small depth of focus is generated (we refer to this as AS configuration).

To achieve a wide incident beam orientation, a thicker laser line with a large depth of focus is generated (we refer to this as AF configuration). This configurability along with variation on lens properties (focal length, etc) allows for a wide variation of customer laser line requirements.

Conclusion

For the most part, using cylindrical lenses are sufficient for certain customer applications. However, if your application requires uniform distribution of light, a structured light laser is required.

ProPhotonix is a leading designer and manufacturer of Laser Diodes, Laser Modules, UV LED Curing Systems, LED Products, and UVC LED Disinfection Systems. Contact us for free expert advice on selecting the optimal solution for your system.

ProPhotonix laser module range includes laser modules by beam shape including crosshair lasers, line lasers and dot laser modules. Contact us for free expert advice on selecting the optimal solution for your system.