UVC disinfection primarily works by creating lesions in the DNA of microorganism’s interfering with the DNA replication process leading to inactivation or death. UVC LEDs also work indirectly by creating reactive oxygen species which causes oxidative stress on cells leading to cellular damage and/or cell death.

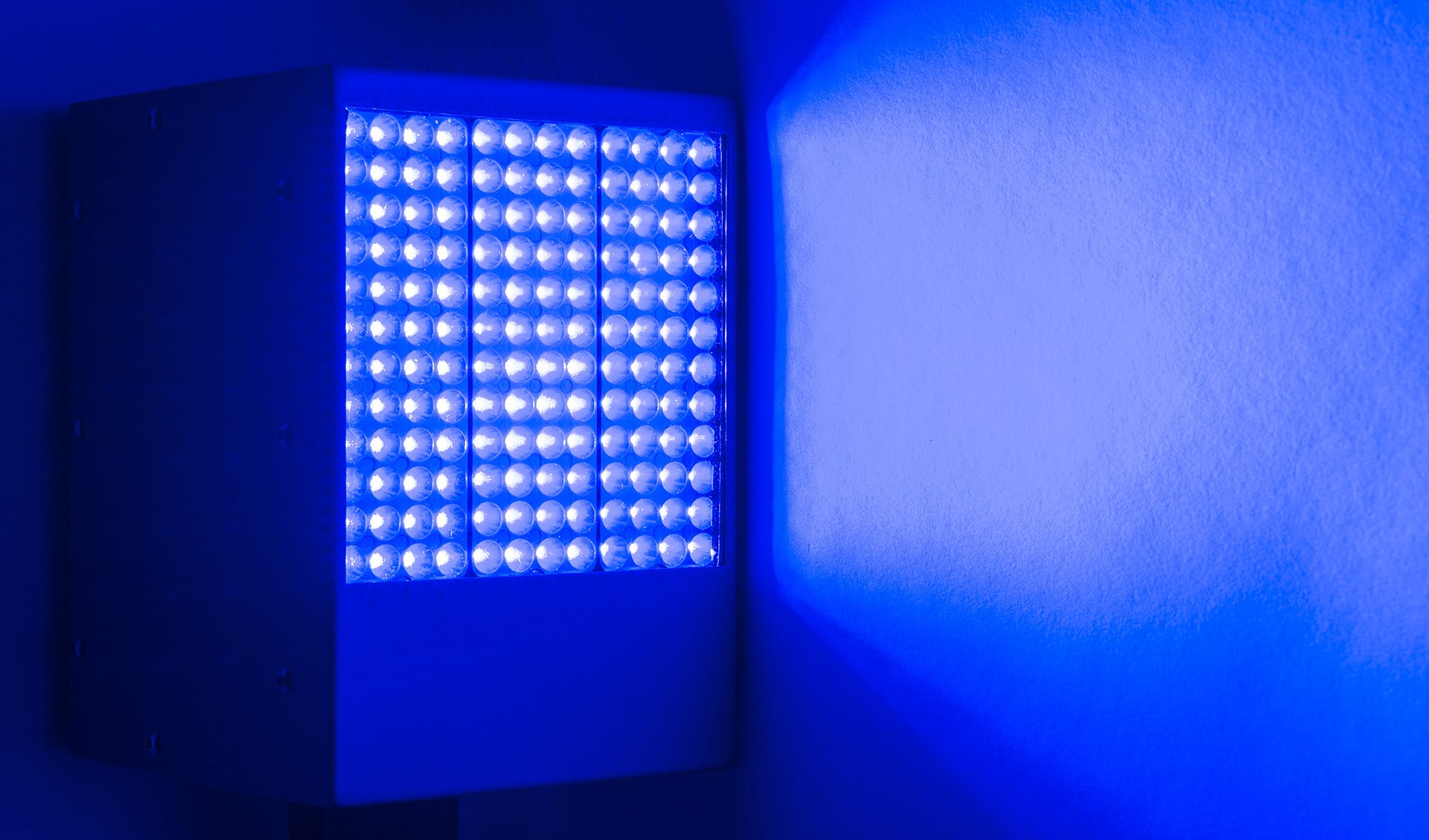

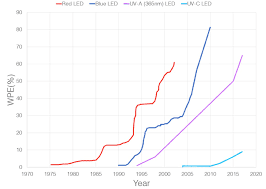

UVC LED disinfection systems are increasingly used across a wide range of sectors for air, food, surface and water disinfection due to the inherent advantages of a LED solution. They are a more sustainable option due to the environmental considerations (no ozone emissions or mercury content) and reduced energy usage. In addition, UVC LEDs have a longer lifetime than mercury alternatives.