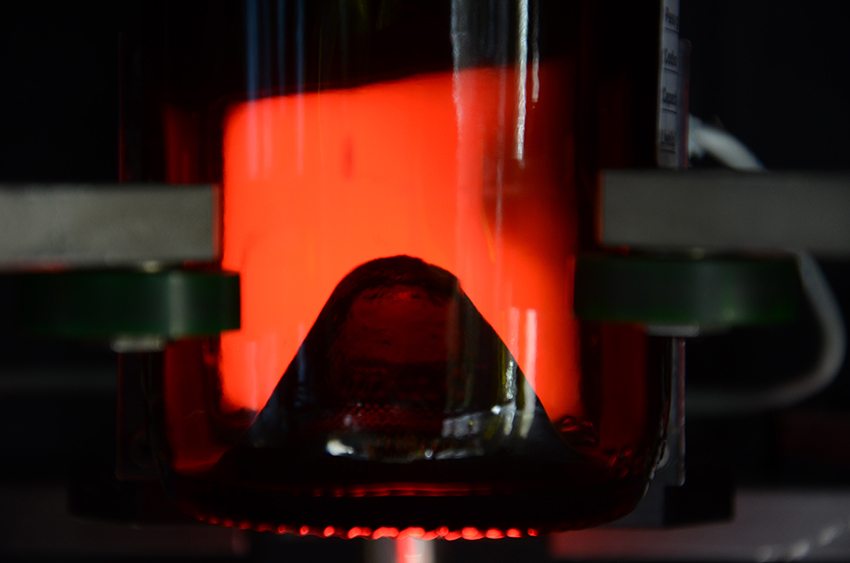

Infrared machine vision lighting enables vision systems to recognize objects and their condition under difficult lighting conditions, for example, reflective surfaces that produce high levels of visible-spectrum noise, high or low levels of illumination, or target areas with variable light intensities.

Wide range of LED and Laser solutions for Infrared Machine Vision Lighting

Why use infrared imaging?

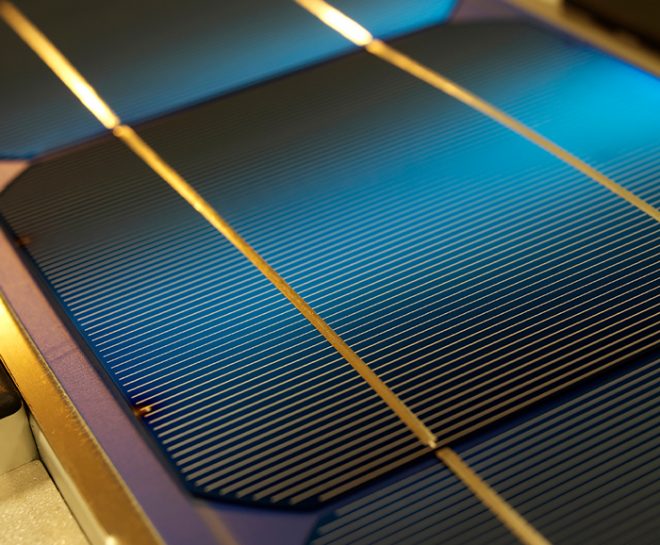

IR has a longer wavelength than visible light so can transmit further into certain materials such as glass, semiconductor, paper, cloth and plastic. As a result, certain defects or flaws can be detected with IR which cannot be seen with visible light.

Machine Vision System Considerations

When building an IR vision system, the correct combination of camera, lighting and software components must be considered. For cameras, the speed of measurement, level of sensitivity and price are important factors when deciding on the optimum system configuration. The choice of lighting directly affects the choice of camera since different camera sensors have different optimum wavelength sensitivities.

Infrared Machine Vision Lighting Considerations

Designing any machine vision system is as much about managing trade-offs as it is about optimizing the system’s performance at an acceptable cost.

Wavelength

The material under inspection determines the range of wavelengths that can be utilized as different materials absorb different wavelengths more easily. It is important to choose your wavelength correctly as even wavelengths a few nanometers apart can have wide variations in price and optical efficiency.

Scene considerations

Once the wavelength or wavelengths have been selected, the overall scene to be illuminated needs to be examined to ensure the illumination solution captures the relevant information in the camera sensor. It is important to consider the size of the illumination area and understand what shadows and reflections will be present during the systems operation. The beam profile, the intensity, the working distance and the positioning of the light are critical to producing the optimum illumination profile. Careful design of the LED layout, lenses and reflectors maximize the modules performance. All of these factors need to be considered while taking into account that there can be strict constraints on the modules form factor when integrating IR illumination modules into OEM systems.

Thermal design

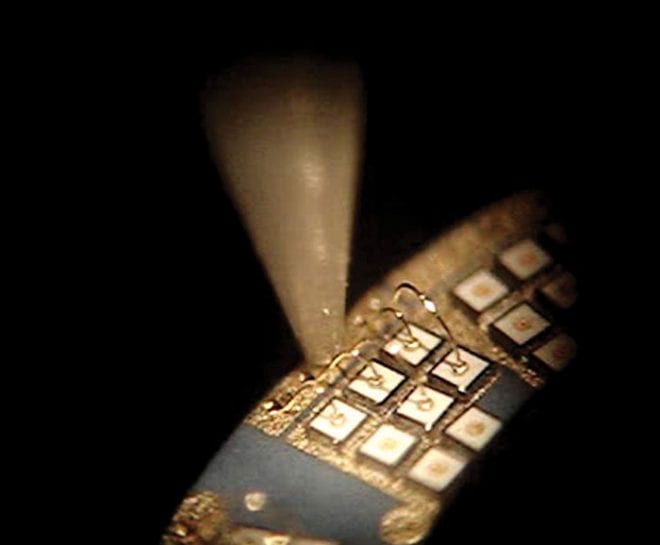

IR illuminators operating at high intensities or located in constrained or enclosed spaces require well-designed heat-sinking. Good thermal design must take the environment, IR LED packing density, specified run time, current drive rates, strobe flash, and correct heat-sink material into consideration. With this information, ProPhotonix will develop the optimum solution to maximize the efficacy of the LED illuminator and longevity of the LED chips.

Custom IR Machine Vision Lighting

ProPhotonix specializes in developing custom IR LED solutions to maximize our customers’ system performances by focusing on wavelength precision, uniformity control, power management, and miniaturization.

Need help to optimize for your application?

For comprehensive technical support. Talk to us.

Contact UsContact Us

Bernhard Russell

Inside Sales

Andrea Gregorio

Inside Sales