Machine Vision Lighting in Food & Beverage

With ever-increasing quality, traceability, and safety requirements in the food and beverage industry, and improvements in technology, the contribution that machine vision can make to businesses looking to improve efficiencies and performance, continues to grow. In applications such as inspection, sorting, and grading, machine vision systems can enable higher inspection rates, increased throughput, and improved quality. Recent advances in multispectral and hyperspectral imaging have further expanded the range of solutions available for this industry.

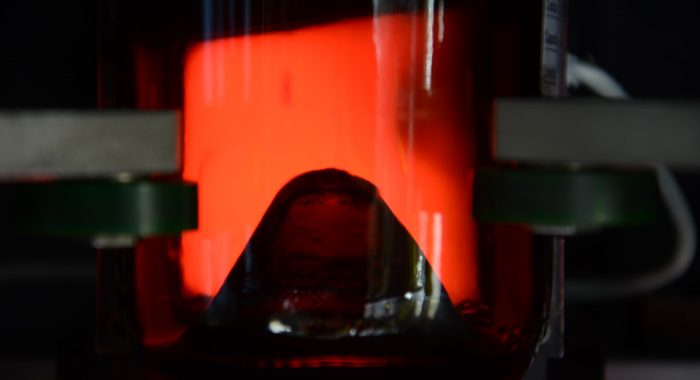

The Role of Machine Vision Lighting

The purpose of a machine vision system is to identify certain features of interest in the target material. The performance of the system relies on obtaining a “good image” but how do we define a good image? A “good” image is an image that highlights the features of interest, allowing the system software to quickly and easily identify any issues, for example, a defect in the item under test. This is primarily achieved by enhancing the contrast between the features of interest, and the background and ensuring sufficient signal (light intensity) for the image to be detected. Wavelength, uniformity, angle of illumination, and intensity are critical to maximizing contrast, and obtaining a good image can result in faster processing times, faster line speed, and a more robust and reliable quality control process.