ProPhotonix has recently launched a new high power UV LED Curing Lamp, COBRA Cure FX1 Max, that offers 20% higher intensity in the same compact form factor as the COBRA Cure FX1. This post highlights the features and benefits of the new UV LED Curing System.

Intensity and Dose

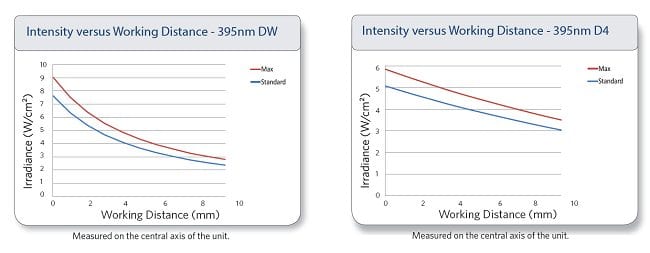

COBRA Cure FX1 Max delivers intensities up to 6.4W/cm2 and a factory-set dose of up to 7.8J/cm2. This increased output has been achieved without any increase in the compact form factor design of COBRA Cure FX1. The charts below show the comparable intensity levels, at different working distances, for both the COBRA Cure FX1 and the new COBRA Cure FX1 Max lamps.

ProPhotonix utilizes Chip-on-Board LED technology in its COBRA Cure FX Series. Using this LED packaging method, ProPhotonix works with the bare LED chip to design and manufacture densely packaged LED arrays. With this latest release, ProPhotonix has utilized its expertise in Chip-on-Board LED array design and packaging to deliver the optimum solution for applications where space is restricted but higher intensity and dose levels are required.

A number of intensity profiles are available with the COBRA Cure FX1 Max. Read this post for more information on intensity profiles.

Form Factor

In many applications, space is a premium. At just 77 X 28 X 120mm, COBRA Cure FX1 Max retains the slim and compact footprint of COBRA Cure FX1 making it well suited to applications with limited available area.

Benefits of a UV LED Curing System

UV LED curing systems offer a more sustainable solution than traditional technologies with no mercury content or ozone emissions. Operational costs are lower as UV LED systems offer longer lifetimes, significant energy savings, and less downtime for maintenance. If you need a curing system for thin films or heat sensitive substrates, a UV LED solution may be preferable due to its cold cure technology.

Lifetime

ProPhotonix understands the importance of product lifetime, as one of the key advantages of selecting a UV LED Curing system, in ensuring repeatable performance in your system. The Optical, Mechanical and Electronic engineers at ProPhotonix developed and optimized the design and manufacturing processes increasing the COBRA Cure FX1 Max’ intensity and dose without compromising on lifetime.

Applications

COBRA Cure FX1 Max’ combination of higher intensity and dose, as well as a compact form factor, make it ideal for UV curing in printing and 3D Printing applications as well as UV curing of coatings and adhesives.

For more information about the COBRA Cure FX1 Max:

About the COBRA Cure FX Series

ProPhotonix has a long history of working with OEMs to provide optimized LED solutions for their systems and more than 15 years of experience working with UV LEDs. The COBRA Cure FX series incorporates this wealth of experience offering reliably, high performance along with ease of installation a number of unique features. Learn more about the COBRA Cure FX Series.

The COBRA Cure FX Series has been designed with multiple mounting options allowing the lamps to be set to the optimum working distance for the application. The COBRA Cure FX1 series is UL, CE and IEC certified.