UV LED technology provides an ideal solution for UV curing of adhesives in electronics assembly. Easily integrated into the assembly process, UV LED Curing systems, provide an even, reliable cure and the “cold cure” delivered is ideal for heat-sensitive components.

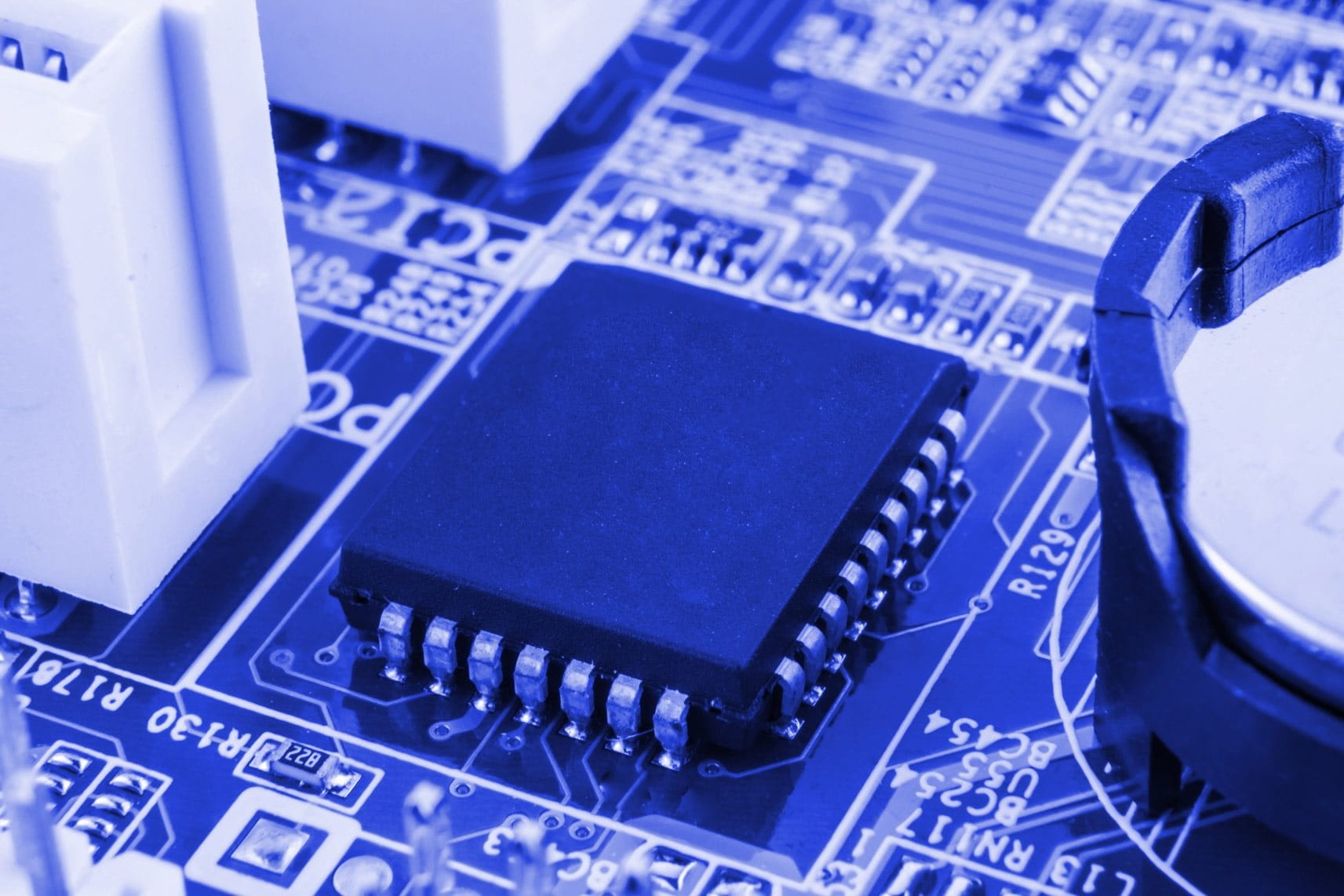

Die Attach (often referred to as die bonding) is the process of attaching a die/chip to a substrate or package. Die attach can be accomplished by UV curable adhesive. It has the main advantage of being curable in situ, thereby significantly speeding up the entire assembly process and opening up the range of applications to some specific cases. The use of UV LED curing lamps in these applications can provide a fast, reliable cure.

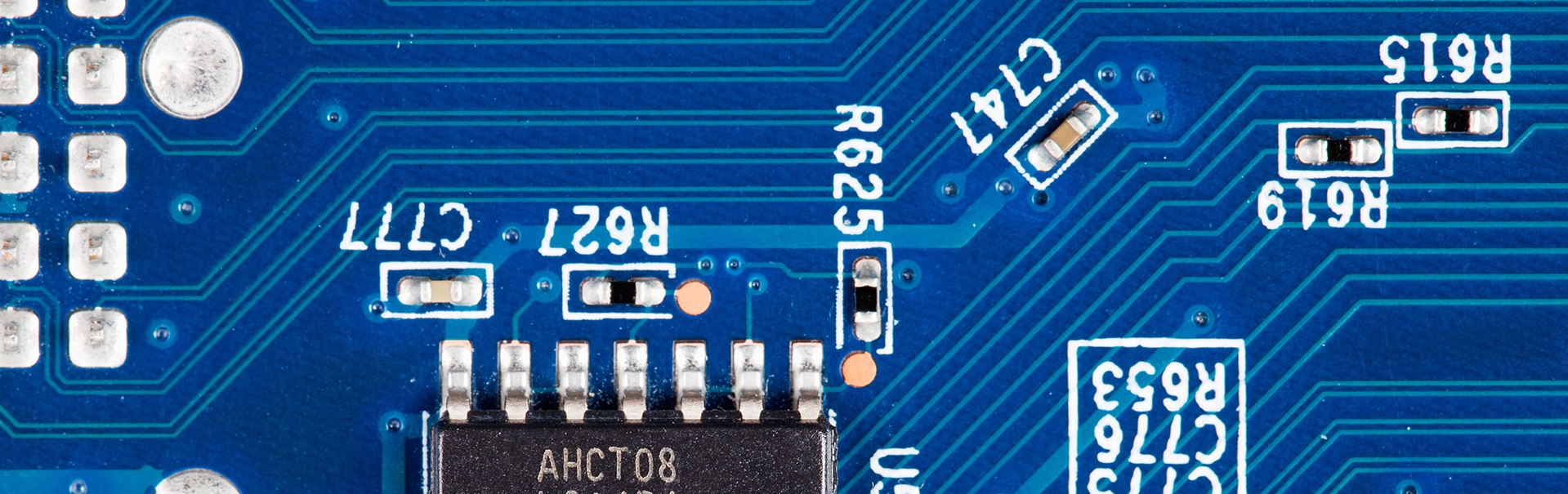

Surface Mount Adhesives (SMD Adhesives) Before soldering, components with pin contacts or SMDs are often bonded to the PCB with adhesive. This allows components to be positioned on a circuit board and cured within just a few seconds to prevent their falling over or sliding out of position on the PCB. The secured components can then be reflow-soldered in a single work step, which saves time and speeds up production. With their compact nature and long lifetimes, UV LED curing lamps are easily integrated into these applications providing a uniform cure for tens of thousands of hours.

Underfill resins are used to reduce the thermal expansion mismatch between silicon chips, solder balls, and the substrate. To compensate for this mismatch, a liquid underfill resin with a Coefficient of Thermal Expansion (CTE) close to that of the solder bump is deposited and UV cured in the gap between the chip and substrate. The use of underfill enables structural coupling of the chip and substrate, effectively decreasing the shear stress and thus lowering the applied strain on the solder joints. UV LED curing lamps offer an ideal solution for these applications.