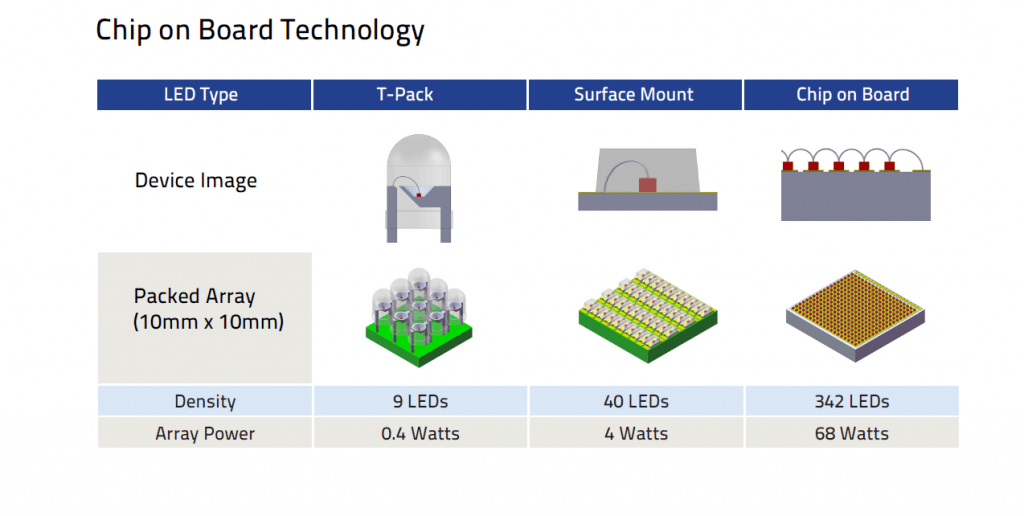

LED arrays are assemblies of LED packages or chips that can be built using several methods. The method is determined by the manner and extent to which the LED chips themselves are packaged by the LED semiconductor manufacturer. The intensity & uniformity of light output, as well as the size of LED array, varies depending upon the method of LED array manufacturing used.

Types of LED Arrays

The LED array method that should be used for any given application depends on the light output requirements, the space available for the illuminator, as well as other factors.

Arrays of packaged LEDs can provide adequate intensity and uniformity for some applications, particularly where the working distances are longer. However, in more challenging applications, such as machine vision lighting applications and medical applications, Chip-on-Board LED arrays provide the highest intensity and best uniformity in the most compact form factor.

Compact LED arrays

With Chip-on-Board LED arrays, the dies (chips) are attached directly to a thermally efficient substrate. Due to the small size of the LED chip relative to packaged chips, Chip-on- Board LED arrays contain a higher density and number of LEDs resulting in a higher intensity and more uniform light output.

For more information on how Chip-on-Board LED arrays compare to surface mount technology, see our blog post on The Advantages of Chip on Board vs Surface Mount technology.

With more than 20 years of experience in developing Chip on Board LED solutions, ProPhotonix has the expertise in optical, mechanical, and electronic engineering to provide the optimum Chip on Board LED solution.