Machine vision systems using high quality LED and laser modules increase throughput and reduce costs in many processes in solar cell production. Vision systems are used in sorting and grading of solar cells and to guide robotic handling equipment.

ProPhotonix provide a range of LED and Laser modules ideal for Solar Cell Inspection

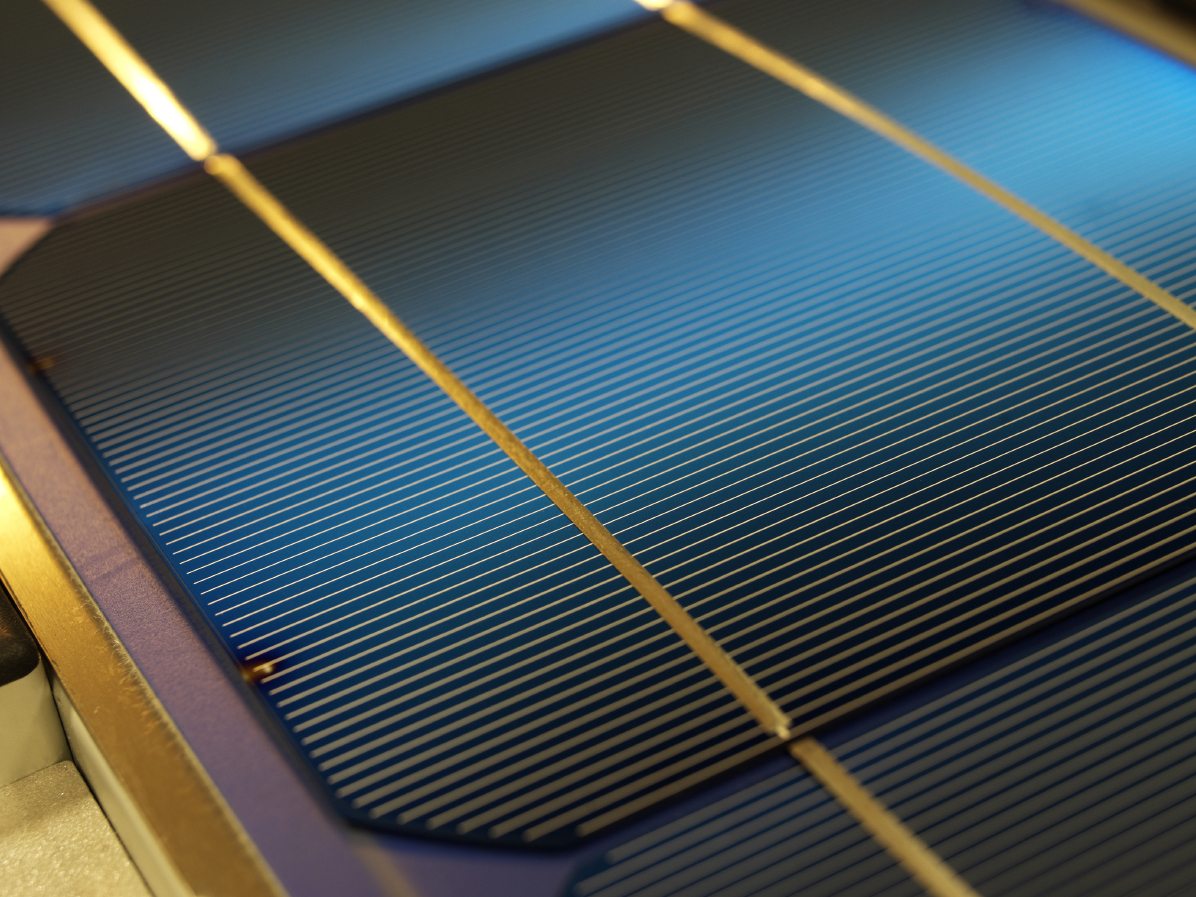

Solar Cell Inspection

The efficiency and optical yield of a solar cell can be significantly impacted by the presence of defects in the raw silicon material. These may include micro-cracks, saw marks, edge defects and inclusions. Machine vision systems are used to enhance quality standards in solar cell manufacturing systems, by detecting flaws in the raw silicon materials. As solar cells require different panels to work together, if inspection systems do not accurately detect defects early whole modules can be compromised.

The success of automated optical inspection systems is largely reliant on the quality of illumination utilized. It is essential that illumination is provided at the correct wavelength, is of adequate power and provides uniform light.

ProPhotonix lasers and LED lighting can be used in inspection processes like:

- 3D wafer sawmark measurement

- Wafer micro crack inspection

- 3D surface measurement

- Wafer geometry inspection

3D Surface Measurement

3D measurement is often used in the PV industry to determine the surface finish of solar cells. 3D PRO™ Lasers provide an ideal solution for solar cell inspection providing uniform narrow lines, enhancing resolution of the images and ensuring that measurements are accurate and defects are detected early.

UV and IR Lights

Inspection of solar cells provides challenges for illumination because the materials being inspected are designed to absorb light and the surfaces are highly reflective. IR and UV lighting are extremely useful in this industry. IR illumination penetrates silicon allowing micro-cracks below the surface to be detected. UV lighting is ideal for solar cell inspection as it reflects well in spite of the anti-reflective coatings on the cells. Red, White and other wavelengths are also used in this industry depending on what is being inspected.

COBRA™ Slim is available in wavelengths from 365nm to 1550nm depending on your application and is ideal for use in line scan illumination in the solar industry. Its high intensity ensures fast effective inspections.

Need help to optimize for your application?

For comprehensive technical support. Talk to us.

Contact UsContact Us

Bernhard Russell

Inside Sales

Andrea Gregorio

Inside Sales